2025 Custom Hardware Buyer’s Guide: How Shenzhen Sunmy Solves 30 Top Pain Points for Global Clients

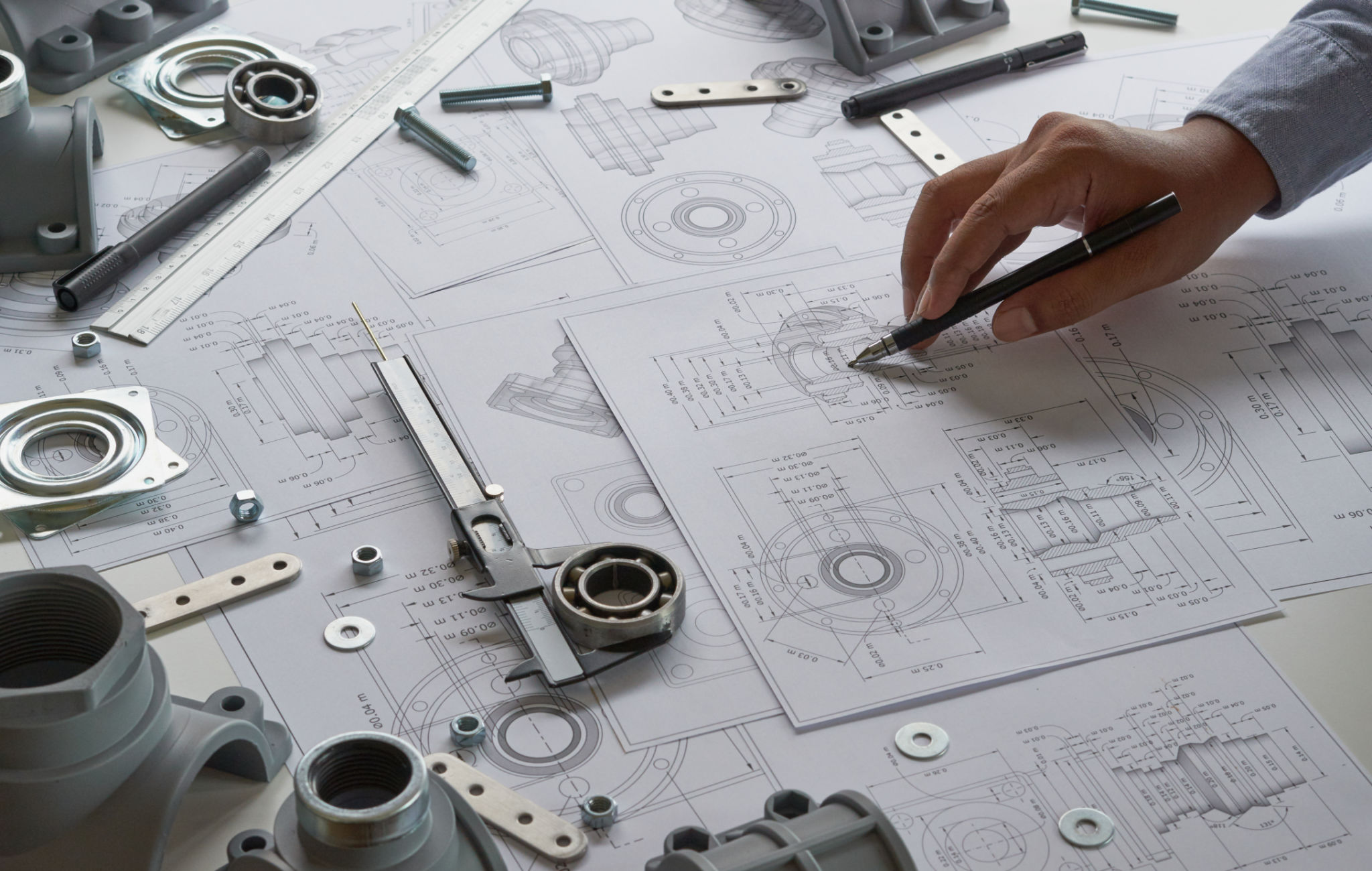

For global buyers seeking custom hardware parts, 2025 brings no shortage of challenges—unreliable suppliers, quality inconsistencies, delayed deliveries, and hidden costs top the list. But since 2016, Shenzhen Sunmy Hardware Co., Ltd. (sunmyhardware.com) has built a end-to-end solution to address these 30 critical pain points, leveraging our industrial-trade integrated model, in-house production, and customer-centric services. Whether you’re sourcing precision components for automotive, electronics, or aerospace, we turn your frustrations into seamless partnerships.

1. Supply Chain & Sourcing: Eliminate Uncertainty, Streamline Collaboration

Global hardware buyers often struggle with fragmented supply chains, miscommunication, and lost control over production. Our integrated approach fixes this:

• Strict Supplier & Production Oversight: We combine our own manufacturing system with long-term trusted partner factories, ensuring every supplier undergoes rigorous screening—no more risky, unvetted vendors.

• Industrial-Trade Dual Role: As both a factory and foreign trade company, we bridge production and global client needs: we manufacture in-house and provide professional international customer support, cutting out middlemen.

• Global Standard Expertise: With years of experience serving cross-border clients, we’re well-versed in international specifications (e.g., ANSI, DIN, ISO) — no more mismatched standards or rework.

• Controllable Lead Times: Our robust production scheduling and project management system keeps you informed at every step; delivery timelines are transparent, not guesswork.

• Flexible Ordering: We support small-batch customization and rapid prototyping, slashing your trial-and-error costs (perfect for new product launches).

• Bilingual Technical Team: Our staff is fluent in technical English, eliminating misunderstandings between your design team and our production floor.

• End-to-End Export Support: We handle customs clearance, international shipping, and certification documents (e.g., CE, FCC) — you avoid export risks and administrative headaches.

2. Product Quality & Design: Build Reliable, Compliant Components

Poor material quality, inconsistent finishes, and failed functionality can derail your projects. We prioritize quality at every stage:

• High-Grade Raw Materials: We rigorously select material suppliers to ensure thickness, hardness, and durability meet your exact standards—no cutting corners on base materials.

• Advanced Surface Treatments: Choose from electroplating, spraying, polishing, and more; our processes enhance corrosion and wear resistance, extending part lifespan.

• Proven Functionality: Every component undergoes repeated durability testing (e.g., load-bearing, shock absorption) to guarantee stable performance in real-world use.

• Full-Cycle Quality Inspections: We implement IQC (Incoming Quality Control), IPQC (In-Process Quality Control), and FQC (Final Quality Control) — minimizing defect rates to near-zero.

• Sample-to-Mass Consistency: We track every step from prototype to trial production to mass manufacturing, ensuring the parts you receive match your approved sample.

• Strong R&D Capabilities: Our team excels at developing custom solutions from your drawings or physical samples, even creating differentiated designs to meet unique needs.

• Global Environmental Compliance: Materials and processes adhere to international eco-standards like RoHS and REACH — keeping your products compliant in global markets.

3. Delivery & Logistics: Get Parts On Time, Intact

Delays, damaged goods, and unclear progress updates cost time and money. We make logistics stress-free:

• High On-Time Delivery Rate: Our ERP system manages order progress in real time, reducing delays caused by mis scheduling or bottlenecks.

• Diversified Logistics Options: We partner with trusted providers for sea freight, air freight, and express delivery — we’ll recommend the most cost-effective option for your timeline.

• Secure Packaging: Our professional packaging designs protect parts from moisture, shock, and damage during transit — no more receiving broken components.

• Batch Consistency: We use the same raw materials and processes for each batch, avoiding variations between orders.

• Transparent Production Tracking: We send regular updates on your order’s status, so you always know where your parts stand.

4. Cost & Pricing: Save Money, Avoid Hidden Fees

Hidden costs, unclear quotes, and rework expenses eat into budgets. We offer transparency and value:

• Cost Advantages from Integration: Our industrial-trade model and in-house production eliminate middleman markups — you pay for manufacturing, not extra layers.

• Transparent Quotations: Every quote clearly lists mold costs, material costs, and shipping fees — no hidden charges or surprise bills.

• Reduced Rework Risks: We confirm samples upfront and enforce strict quality checks, cutting down on costly post-production rework.

• Flexible Pricing Strategies: We adjust pricing based on your order volume and customization needs, ensuring you get a fair deal.

• Exchange Rate Risk Mitigation: We accept multi-currency payments, helping you avoid losses from currency fluctuations.

5. Service & After-Sales: Partner for Long-Term Success

Poor after-sales support and unaddressed issues ruin partnerships. We stand behind our products:

• 24-Hour After-Sales Response: Our team replies to After-sales serviceinquiries within 24 hours, resolving issues quickly to keep your operations on track.

• Comprehensive Technical Support: We provide installation guidance and drawing optimization suggestions — not just parts, but expertise.

• Traceable Quality Issues: Our full production traceability system lets us pinpoint the root cause of any quality problem, with clear accountability.

• Rapid Replacement Parts: We stock common parts, shortening lead times for replacements when you need them.

• Long-Term Partnership Focus: We prioritize long-term win-win relationships, not one-time orders — we grow with your business

6. Industry Trends: Stay Ahead with Forward-Thinking Solutions

In 2025, falling behind on smart manufacturing or eco-friendly trends means losing competitiveness. We keep you ahead:

• Future-Focused R&D: Beyond traditional custom hardware, we invest in developing smart components (e.g., sensor-integrated parts) and eco-friendly materials — helping you capture emerging market opportunities.

Ready to Solve Your Custom Hardware Pain Points?

For global buyers tired of supply chain headaches, quality risks, and hidden costs, Shenzhen Sunmy Hardware is your trusted partner. Visit sunmyhardware.com today to submit your drawings, samples, or requirements — our team will provide a detailed, transparent quote within 24 hours. In 2025, don’t just source parts—partner with a manufacturer that solves your biggest challenges.

Shenzhen Sunmy Hardware Co., Ltd. — Your Solution to 30 Global Custom Hardware Pain Points.