5 Costly DFM Mistakes in Sheet Metal Stamping Design You’re Probably Making (And How to Fix Them)

Sheet metal stamping is the backbone of countless industries—from automotive and electronics to industrial equipment. But even the most innovative product designs can fail at the production stage if they ignore Design for Manufacturability (DFM) principles. At Shenzhen Sunmy Hardware Co., Ltd., a leading Shenzhen-based 工贸 (industry-trade integrated) foreign trade company founded in 2016, we’ve seen firsthand how small DFM oversights lead to delayed timelines, inflated costs, and compromised part quality for our global clients.

With our end-to-end production ecosystem—covering Casting, Lathe, Machining, Stamping, and Injection Molding—and a team specializing in custom part manufacturing (backed by robust R&D capabilities), we help clients turn design concepts into tangible, high-quality products. Today, we’re sharing the 5 most common DFM mistakes in sheet metal stamping design, plus actionable fixes to keep your projects on track. Let’s dive in.

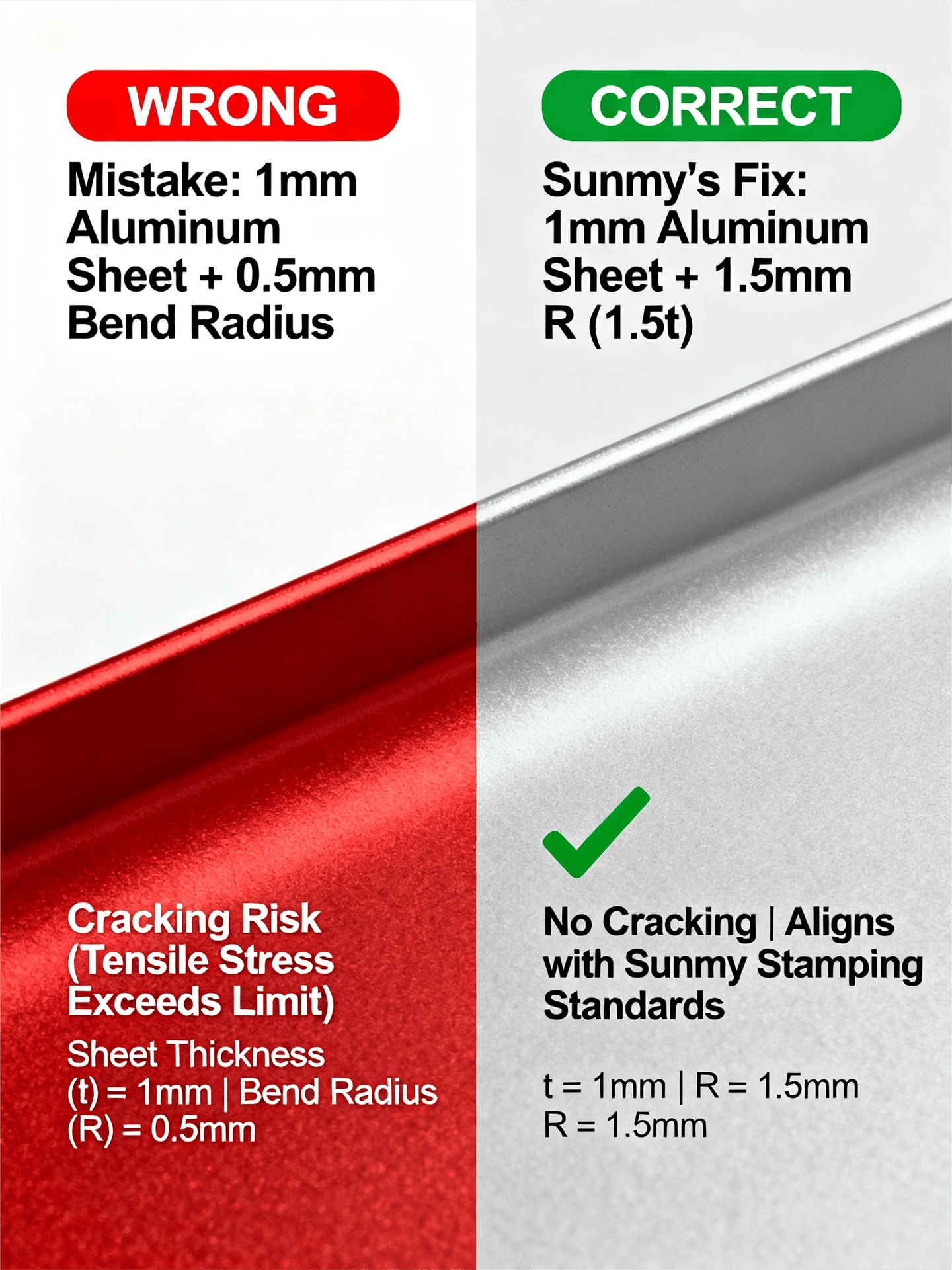

1. Neglecting Minimum Bend Radius: A Recipe for Material Failure

The Mistake:

Many designers specify bend radii smaller than the material can handle, assuming “tighter = better.” For example, a 1mm aluminum sheet with a 0.5mm bend radius might seem efficient, but it risks cracking, warping, or weakening the material’s structural integrity.

The Consequences:

- Scrap rates spike as parts fail quality checks.

- Rework delays production (we’ve seen projects pushed back 2–3 weeks due to this issue).

- Compromised durability shortens the end product’s lifespan.

Sunmy’s Fix:

Our stamping engineers work directly with clients to align bend radii with material properties. For common materials:

- Steel: Minimum bend radius = material thickness (t)

- Aluminum: Minimum bend radius = 1.5t (to avoid cracking)

- Stainless steel: Minimum bend radius = 2t (due to higher tensile strength)

With our in-house stamping equipment, we can also test prototype bends early—ensuring your design works before full-scale production.

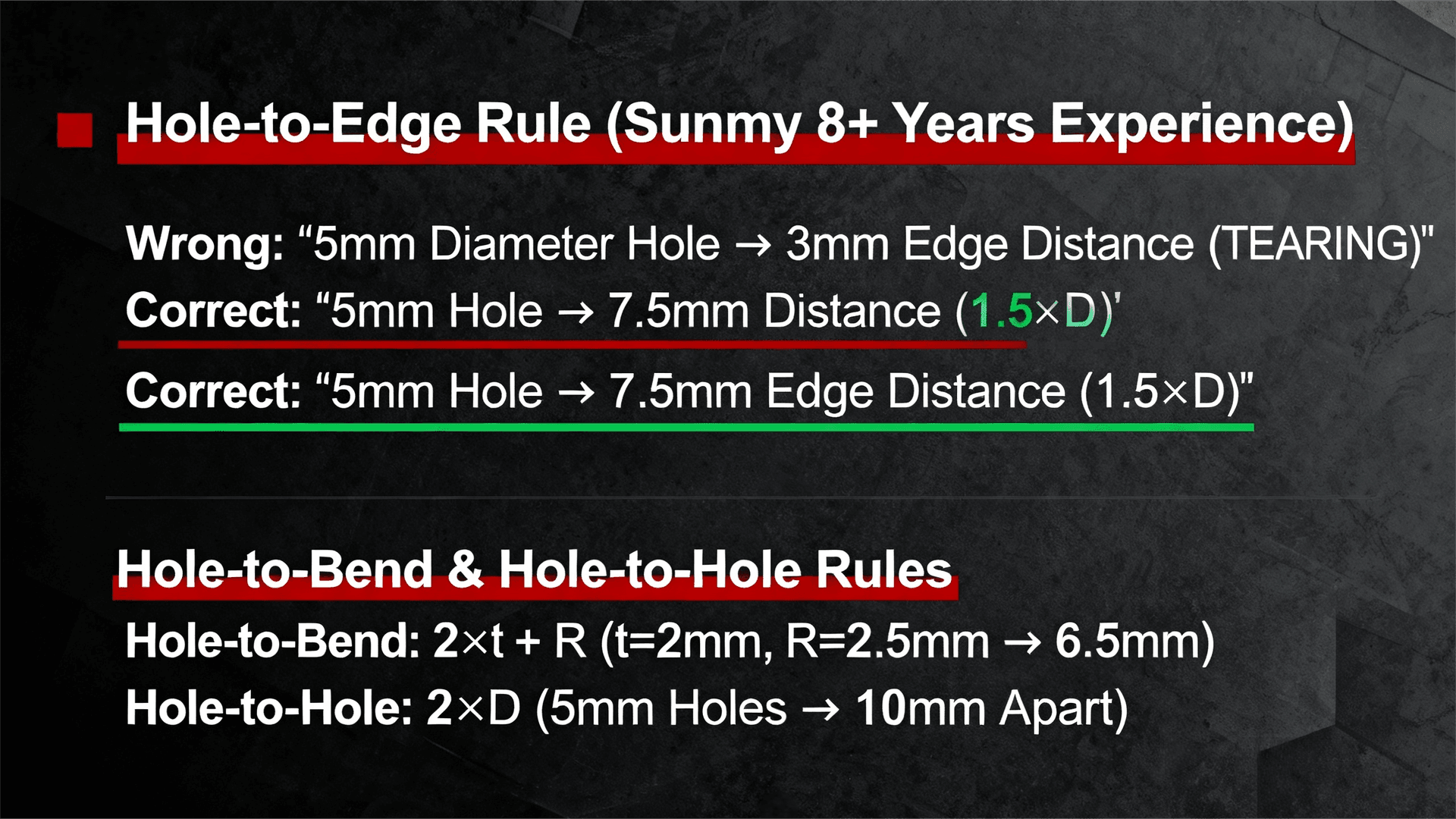

2. Poor Hole Placement: Why “Too Close” Costs You Money

The Mistake:

Holes placed too near edges, bends, or other holes are a top culprit in stamping defects. A common error? A 5mm diameter hole just 3mm from a sheet edge—this creates weak points that cause tearing during stamping.

The Consequences:

- Parts with cracked edges or deformed holes require manual repair (adding labor costs).

- In extreme cases, entire batches are unusable (we once helped a client recover from a 500-unit scrap due to this mistake).

Sunmy’s Fix:

Follow these DFM guidelines (verified by our 8+ years of stamping experience):

- Hole edge to sheet edge: Minimum distance = 1.5 × hole diameter

- Hole edge to bend line: Minimum distance = 2 × material thickness + hole radius

- Between two holes: Minimum distance = 2 × hole diameter

Our team reviews your 2D/3D drawings (or physical samples) upfront to flag risky hole placements—saving you time and material waste.

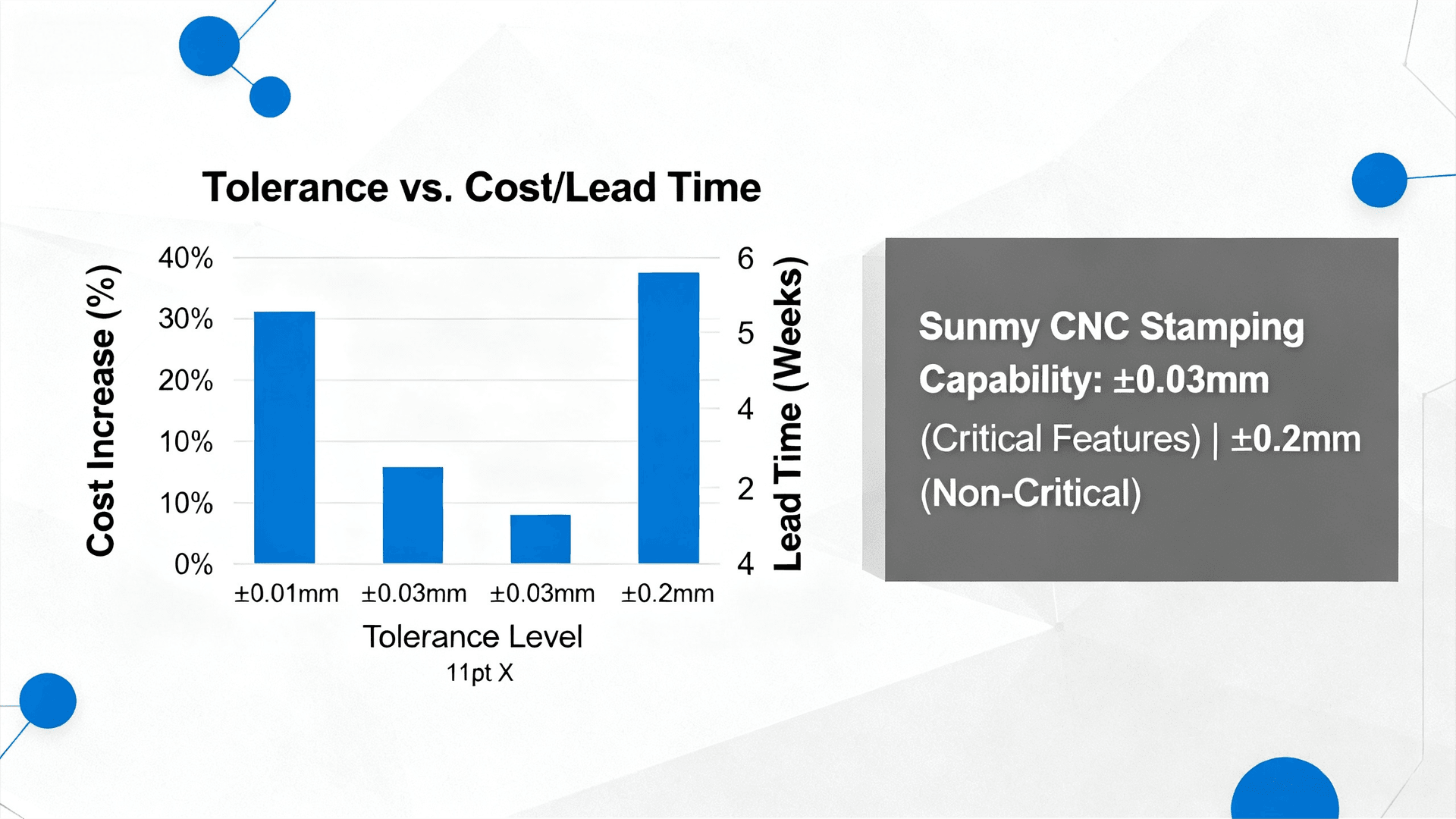

3. Overly Tight Tolerances: When Precision Becomes a Liability

The Mistake:

Designers often specify tolerances tighter than necessary (e.g., ±0.01mm for a non-critical mounting hole) to “ensure quality.” But tight tolerances force stamping machines to operate at slower speeds and require more frequent calibration.

The Consequences:

- Production costs increase by 20–40% (due to slower throughput and higher tool wear).

- Lead times extend—we’ve seen a 4-week project turn into 6 weeks because of unnecessary tight tolerances.

Sunmy’s Fix:

We balance precision with practicality. Our engineers:

- Identify critical vs. non-critical features (e.g., a hinge hole needs ±0.05mm, but a decorative hole can use ±0.2mm).

- Align tolerances with our stamping equipment capabilities (our CNC stamping machines achieve consistent ±0.03mm for critical parts).

- Propose cost-saving adjustments without sacrificing performance—keeping your project on budget and on schedule.

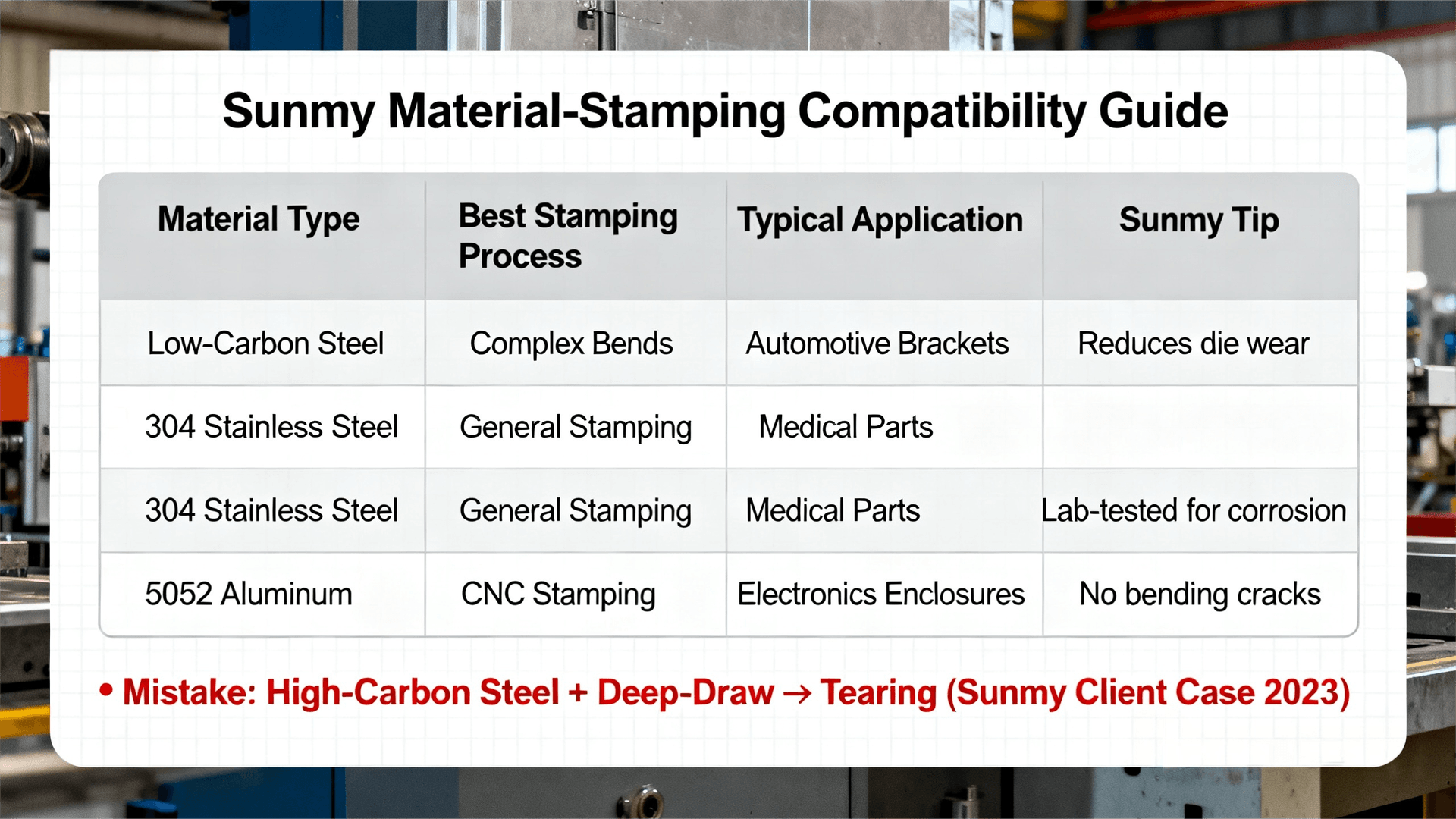

4. Mismatched Material & Stamping Process

The Mistake:

Choosing a material without considering stamping compatibility is a common pitfall. For example, using high-carbon steel (which is brittle) for complex, deep-draw stamping—or thin-gauge copper (which is soft) for high-impact parts.

The Consequences:

- Material tearing during deep draws.

- Parts that deform under stress (e.g., soft copper bending in a heavy-duty application).

- Increased tool wear (abrasive materials like stainless steel damage dies faster).

Sunmy’s Fix:

Our material experts recommend options tailored to your design and application:

- For complex bends: Low-carbonainless steel (durable, compatible with most stamping processes).

- For lightweight applications: 5052 aluminum (strong yet lightweight, ideal for electronics).

We source high-quality materials globally and test them in our in-house lab to ensure stamping compatibility.

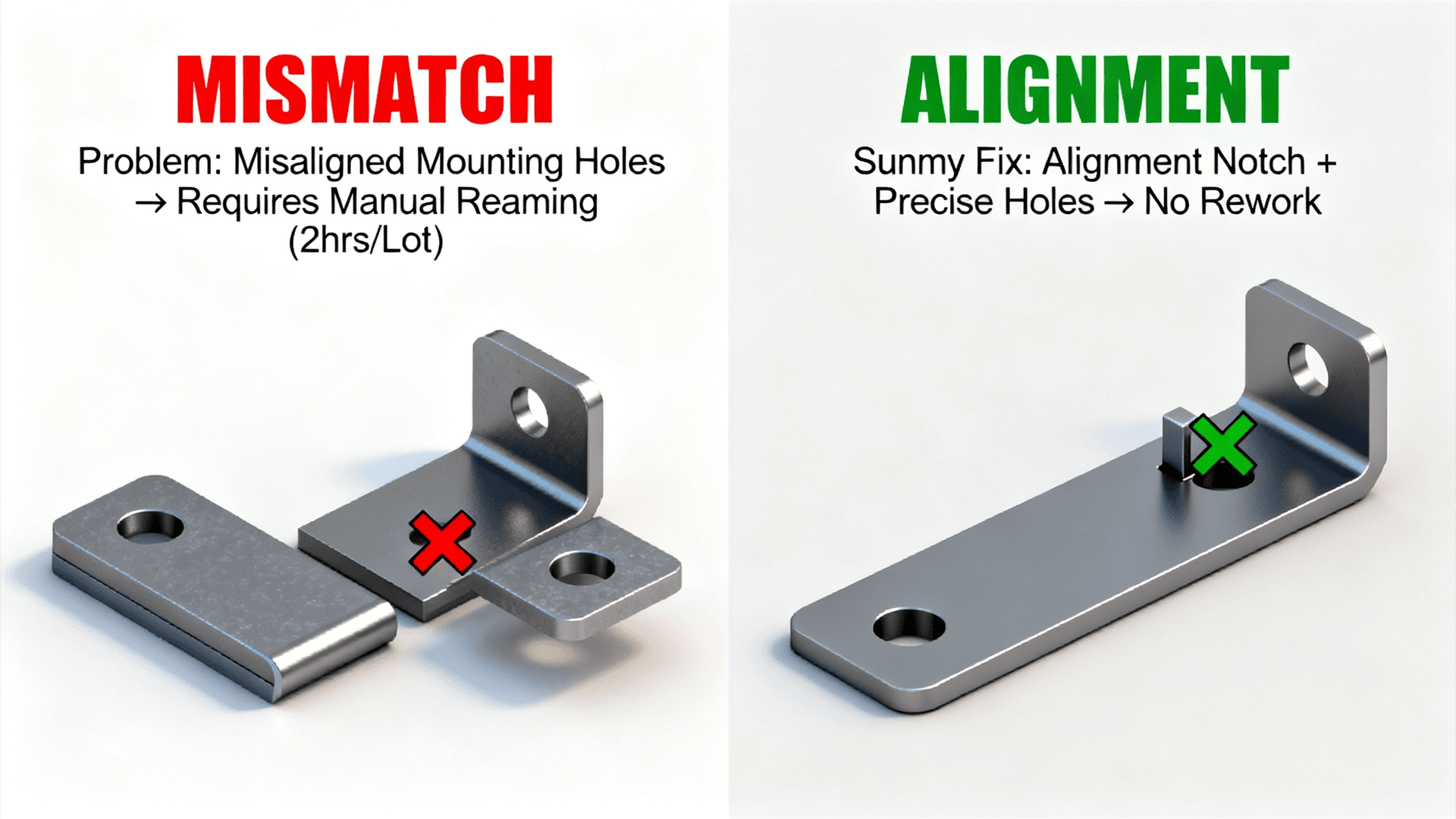

5. Ignoring Post-Stamping Assembly Needs

The Mistake:

Designing a stamped part in isolation—without considering how it will assemble with other components—leads to costly rework. For example, a stamped bracket with a misaligned mounting hole that doesn’t fit a mating part.

The Consequences:

- Manual reaming or grinding to adjust parts (adding labor hours).

- Delayed assembly lines (as teams wait for modified parts).

- Frustration for your end users (if assemblies fail in the field).

Sunmy’s Fix:

We take a “system-level” approach. Our team:

- Reviews your entire assembly (not just the stamped part) to check fitment.

- Adds reference features (e.g., alignment notches) to simplify assembly.

- Creates sample assemblies with your other components to verify compatibility before full production.

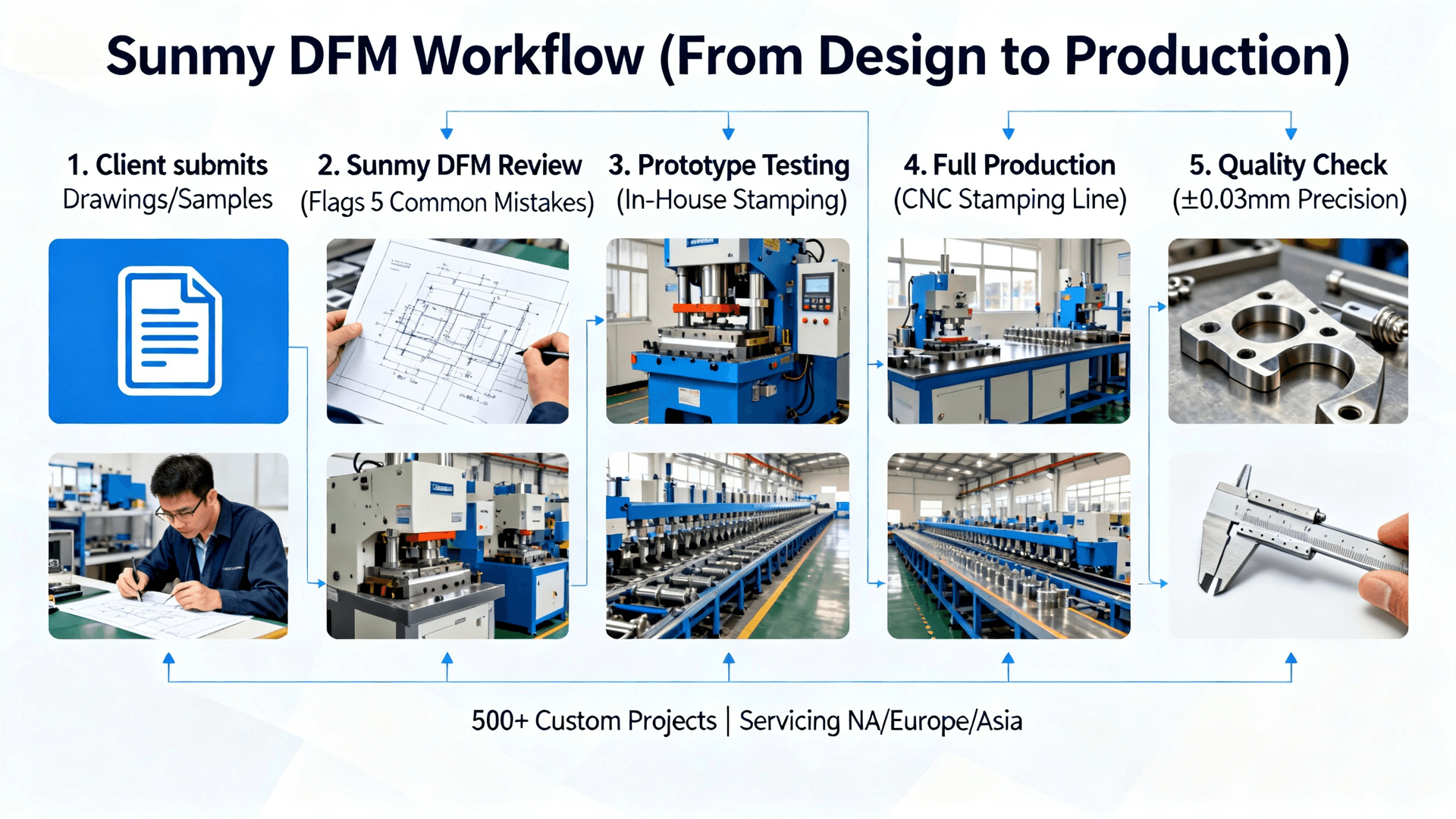

Why DFM Matters—And How Sunmy Helps You Get It Right

DFM isn’t just about avoiding mistakes—it’s about optimizing your design for cost, speed, and quality. At Shenzhen Sunmy Hardware, we’ve built our business around turning complex custom part requests into seamless production experiences. Our strengths:

- End-to-end production: Casting, Lathe, Machining, Stamping, Injection Molding—all under one roof.

- R&D expertise: Our engineering team solves even the most challenging custom designs (we’ve turned 500+ client samples/drawings into mass-produced parts).

- Global service: We support clients in North America, Europe, and Asia—with clear communication and on-time delivery.

Ready to fix your sheet metal stamping design and avoid these costly mistakes? Visit sunmyhardware.com to explore our stamping capabilities, view case studies, or submit your drawing/sample for a free DFM review. Our team is here to help you turn your design into a high-quality, cost-effective product.

Got questions about your sheet metal stamping project? Drop us a line at [email protected] — we respond within 24 hours!