Choosing the Right Custom Aluminum Machining Service for Electronics Projects

Understanding Custom Aluminum Machining for Electronics

When it comes to electronics projects, precision and quality are paramount. This is why many engineers and designers opt for custom aluminum machining services. Aluminum is a preferred material due to its strength, lightweight properties, and excellent thermal conductivity. However, choosing the right machining service can significantly impact the success of your project.

Key Factors in Selecting a Service Provider

There are several factors to consider when selecting a custom aluminum machining service. Firstly, assess the experience and expertise of the provider. An experienced provider will have a proven track record of delivering high-quality components. Additionally, they will be adept at handling complex geometries and tight tolerances, which are often required in electronics projects.

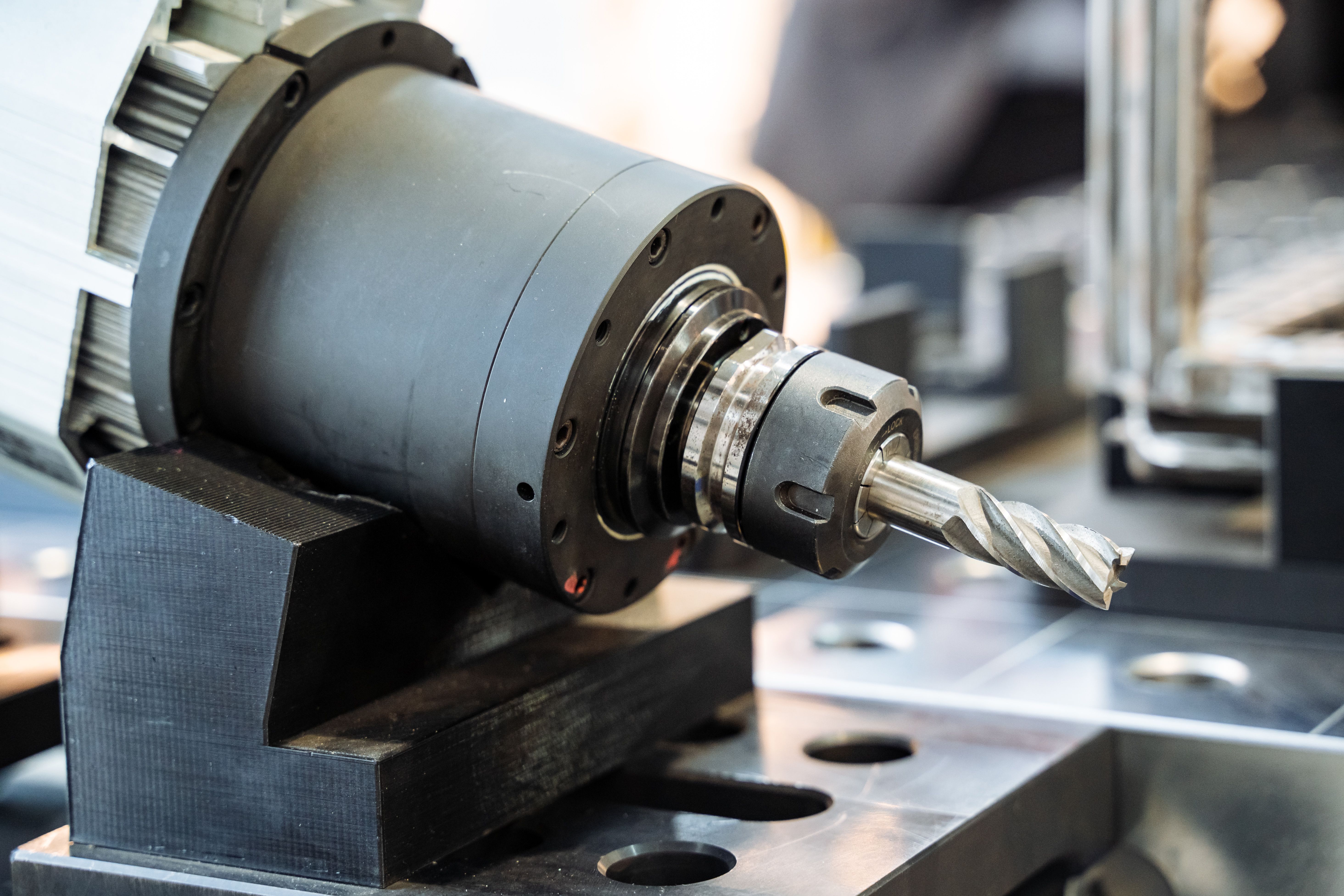

Another crucial factor is the technology and equipment used by the service provider. Advanced CNC machines and modern software tools ensure precision and efficiency in the machining process. It's essential to choose a provider that invests in cutting-edge technology to deliver superior results.

Quality Assurance and Material Selection

Quality assurance is a non-negotiable aspect of custom aluminum machining. Ensure that your chosen service provider follows rigorous quality control processes. Certifications such as ISO 9001 can be an indicator of a commitment to quality standards.

Additionally, consider the range of aluminum materials offered. Different alloys have varying properties that can affect your project's performance. A knowledgeable provider will guide you in selecting the right aluminum alloy that meets your specific needs.

Cost Considerations and Turnaround Time

While cost is an important consideration, it should not be the sole deciding factor. Evaluate the value for money offered by the service. A slightly higher initial cost may be justified by superior quality and durability of the components.

Turnaround time is another critical aspect, especially for time-sensitive projects. Check if the provider can meet your deadlines without compromising on quality. Efficient workflow management and adequate staffing are indicators of a reliable service provider.

Customer Service and Communication

Effective communication is key to a successful partnership with your machining service provider. Choose a company that values customer service and is open to discussing every detail of your project. Clear communication ensures that your requirements are understood and met accurately.

Lastly, review testimonials or case studies from previous clients to gauge the provider’s reputation in the industry. Positive feedback and successful project examples are strong indicators of a reliable service provider.

Making the Final Decision

In conclusion, choosing the right custom aluminum machining service for electronics projects requires careful consideration of multiple factors. By focusing on expertise, technology, quality assurance, cost, turnaround time, and communication, you can make an informed decision that aligns with your project goals. This approach will not only ensure high-quality components but also contribute to the overall success of your electronics project.

Start Your Custom Part Project Today

Every client’s needs are unique—and so are our solutions. As a ISO 9001-certified custom parts manufacturer in China, we ensure quality at every step, from quote to delivery. Our 24/7 team speaks English, German, and Spanish, making communication seamless for global clients.

Ready to turn your drawing into a finished part?

Visit sunmyhardware.com to explore our OEM machining parts, aluminum die casting parts, and stamping project gallery.

Email your design (or sample) to [email protected] for a free quote on USA custom hardware parts, automotive components customization, or any custom need.

Call or Whatsapp +86-18576730322 to chat with a specialist about injection molding solutions or precision machining for medical equipment parts.

Sunmy Hardware: Where custom parts are made with precision, delivered on time, and built to last.