CNC Machining vs 3D Printing for Prototypes: How to Choose the Best Option | CNC Machining China Insights

When developing a new product, choosing the right prototype manufacturing method can make or break your timeline, budget, and final design success. Many global clients we work with at Shenzhen Sunmy Hardware Co., Ltd.—a leading precision hardware manufacturer since 2016—struggle to decide between CNC Machining China services and 3D printing for their prototypes. Both technologies have unique strengths, but the wrong choice can lead to costly reworks, delayed launches, or prototypes that fail to reflect real-world performance. In this guide, we’ll break down how CNC machining and 3D printing work for prototyping, compare their key differences, and help you determine which fits your project needs. We’ll also share how Sunmy’s in-house capabilities—from advanced CNC equipment to rigorous quality checks—support clients in turning prototypes into production-ready parts.

What Is CNC Machining for Prototypes, and How Does It Work?

CNC (Computer Numerical Control) machining for prototyping uses automated, computer-guided tools to remove material from a solid block (metal, plastic, or composite) and shape it into a precise prototype. Unlike mass production, CNC prototyping is optimized for small batches (often 1–50 parts) and quick turnaround, while still maintaining the same high precision as full-scale manufacturing.

At Sunmy, our CNC prototyping process starts with your design:

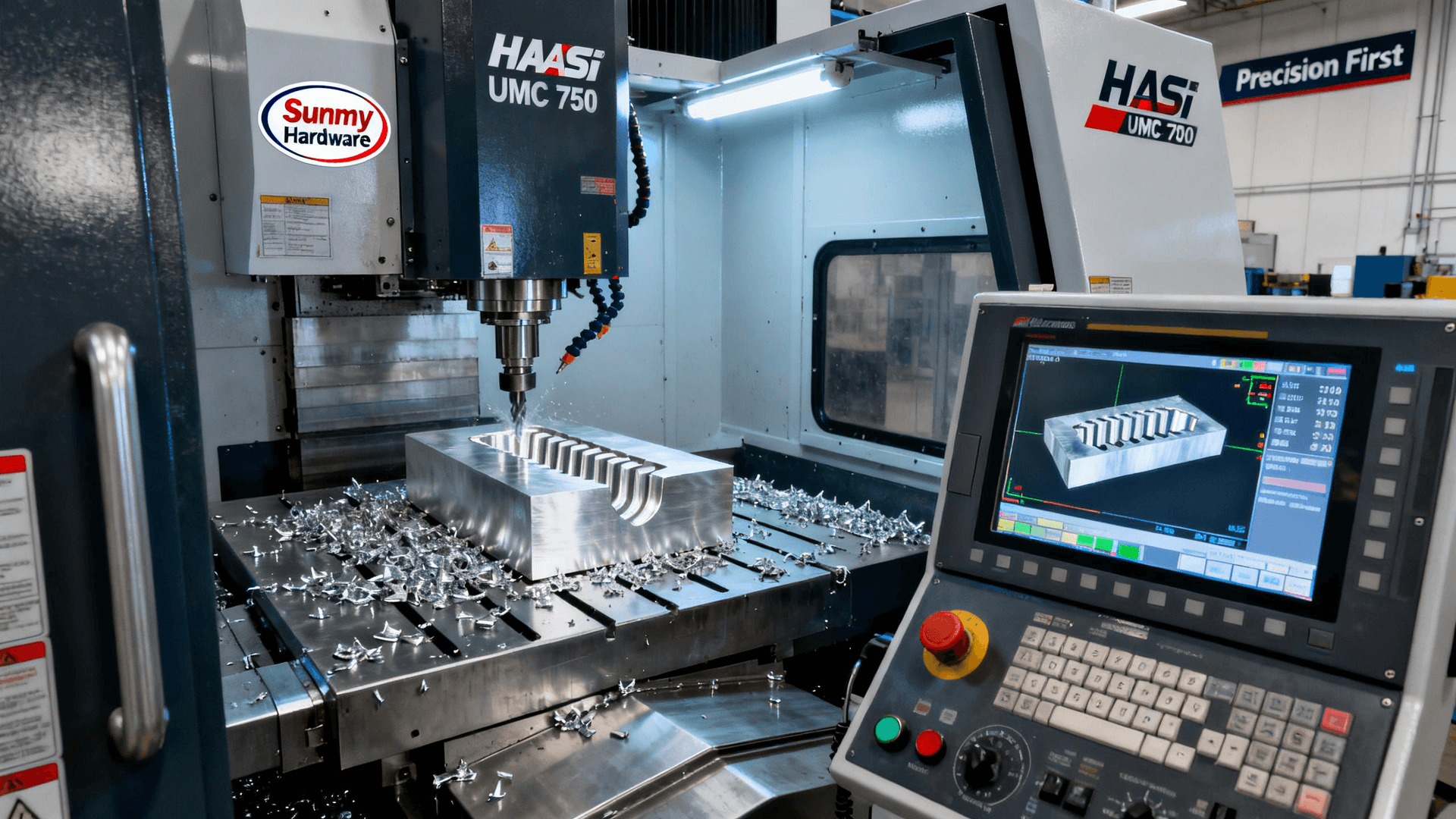

whether you provide a CAD file, 3D model, or physical sample, our engineering team converts it into a detailed toolpath program. We then load this program into our advanced CNC machines—including 5-axis machining centers, vertical machining centers (VMCs), and turning centers—to carve the prototype from raw material. What sets CNC prototyping apart is its focus on accuracy: our machines achieve tolerances as tight as ±0.001mm, and every prototype undergoes in-process checks using tools like digital calipers and coordinate measuring machines (CMMs) to ensure it matches your specifications.

CNC prototyping excels when your prototype needs to mimic the material properties and structural integrity of your final production part. For example, if you’re developing an aluminum automotive bracket, a CNC-machined prototype will use the same 6061 aluminum alloy as the final part, giving you reliable data on strength, weight, and fit during testing. To see our CNC equipment in action, visit our Production Capability page, where we showcase our Haas 5-axis machines and quality control stations.

What Is 3D Printing for Prototypes, and When Does It Shine?

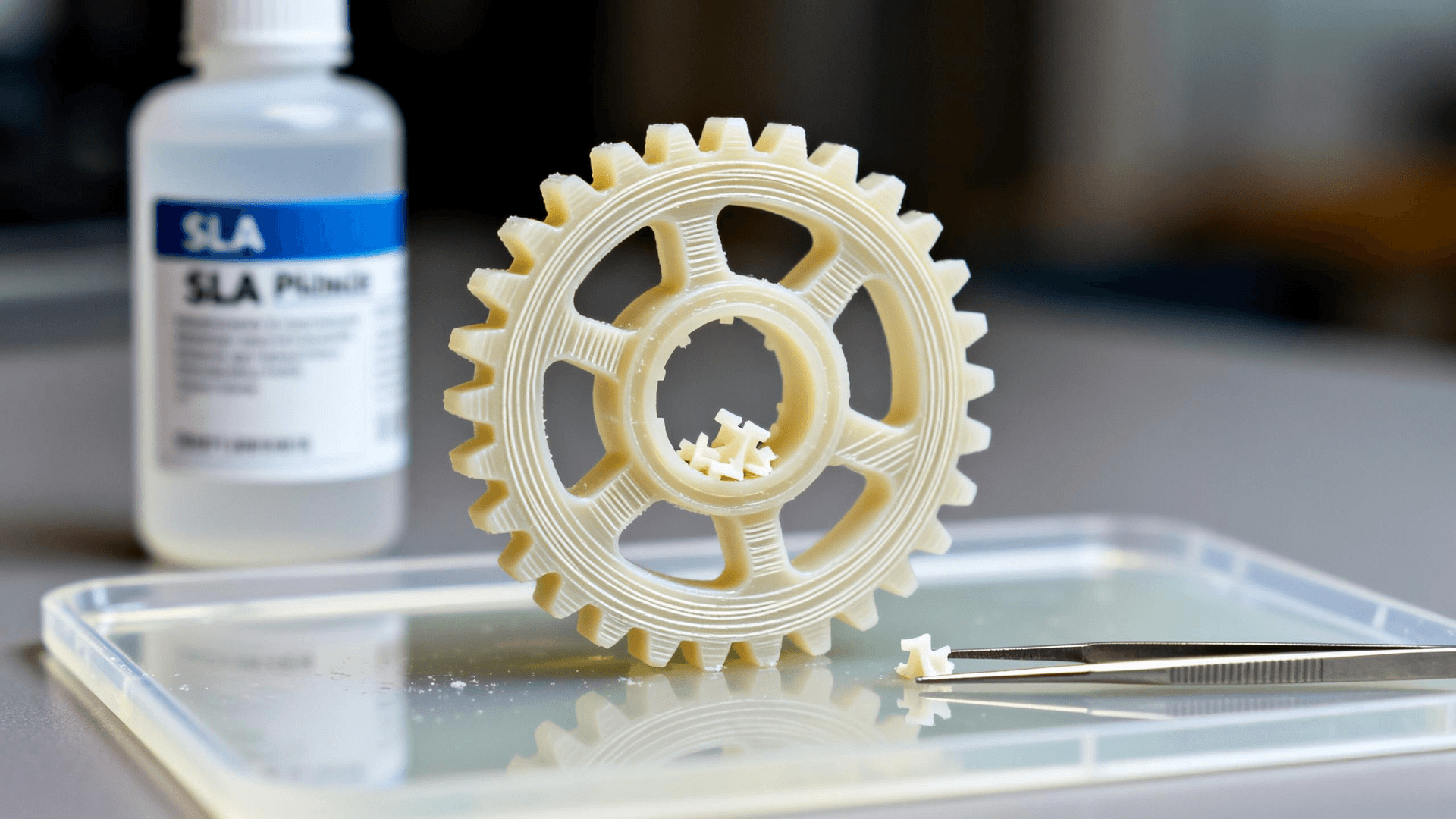

3D printing (additive manufacturing) builds prototypes layer by layer, using materials like resin, PLA, ABS, or even metal powders.

Common 3D printing technologies for prototyping include Fused Deposition Modeling (FDM)—affordable and widely used for plastic parts—and Stereolithography (SLA)—ideal for high-detail resin prototypes. Unlike CNC machining (a “subtractive” process), 3D printing adds material only where needed, making it great for complex geometries that would be difficult or impossible to machine, such as lattice structures or internal cavities.

3D printing’s biggest advantage for prototyping is speed: simple plastic prototypes can often be printed in a few hours, making it perfect for rapid design iterations. For example, if you’re testing the ergonomics of a plastic consumer device, 3D printing lets you tweak the design and print a new prototype in a day—faster than CNC machining for small, simple parts. However, 3D printing has limitations: it struggles with tight tolerances (most FDM printers max out at ±0.1mm), and printed parts are often less durable than CNC-machined ones, especially when using plastic filaments. Metal 3D printing is available but is significantly more expensive and slower than CNC machining for metal prototypes—an important consideration for budget-conscious projects.

Key Factors to Choose Between CNC Machining and 3D Printing for Prototypes

The decision between CNC machining and 3D printing isn’t about which technology is “better”—it’s about which aligns with your project’s specific goals.

Below are the critical factors to consider, with insights from Sunmy’s experience supporting clients across industries like automotive, electronics, and medical devices.

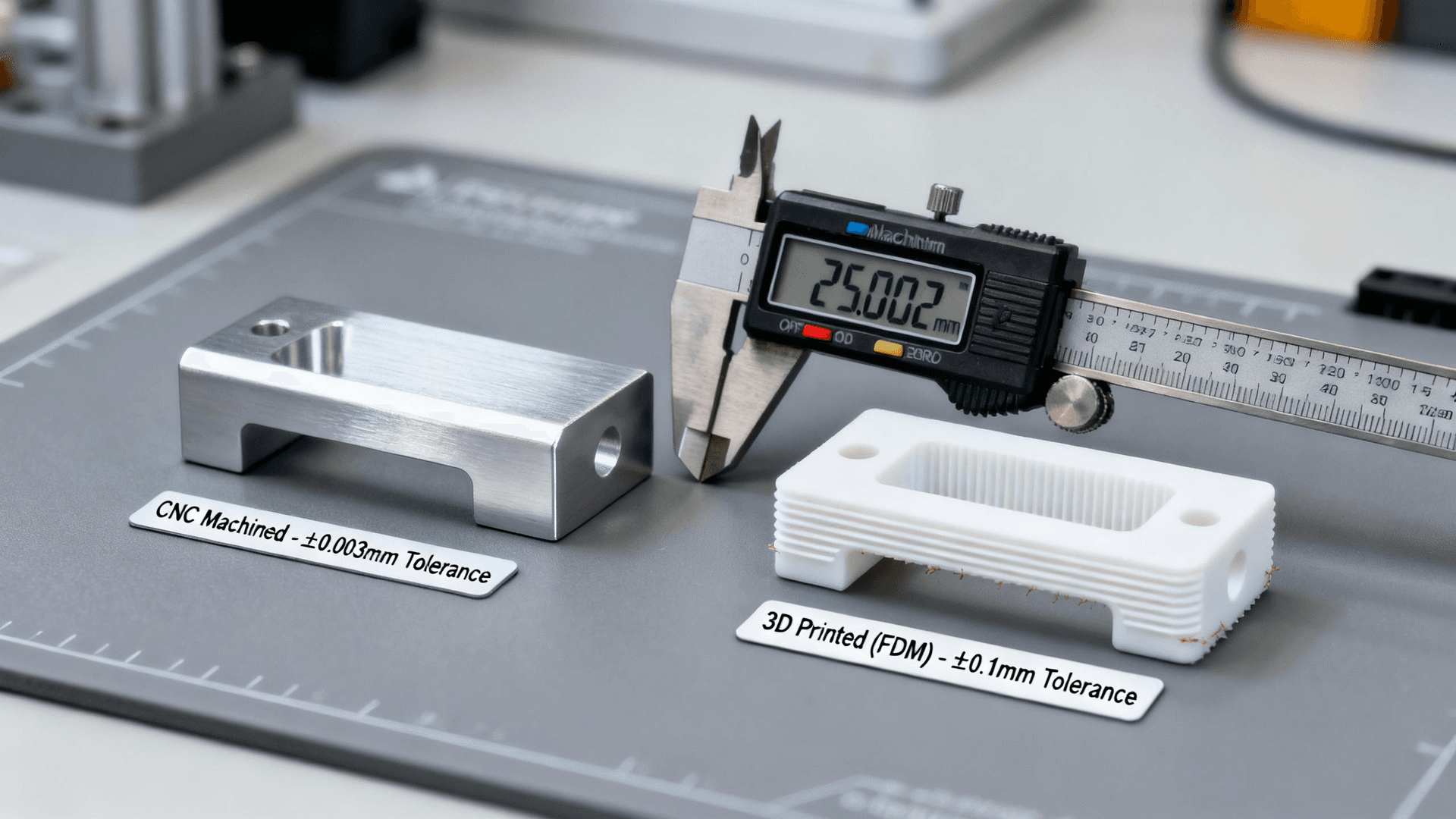

1. Precision and Tolerance Needs

If your prototype requires tight tolerances (e.g., ±0.005mm or smaller) or a smooth surface finish (critical for parts that need to fit with other components), CNC machining is the clear choice. For example, a European client of ours needed a prototype for a stainless steel medical valve—parts that had to seal perfectly to prevent leaks. 3D printing their initial prototype resulted in inconsistent dimensions and a rough surface that failed leak tests; switching to Sunmy’s CNC Machining China service, we produced prototypes with ±0.003mm tolerances and a polished finish, which passed all functional tests on the first try.

3D printing works for prototypes where precision is less critical, such as conceptual models or early-stage ergonomic tests. If your final part will be CNC-machined, however, a 3D printed prototype may not accurately reflect how the production part will fit or perform.

2. Material Compatibility

Your prototype’s material should match (or closely mimic) the material you’ll use for mass production—otherwise, you won’t get reliable data on strength, heat resistance, or durability. CNC machining supports a wide range of materials, including metals (aluminum, stainless steel, brass, titanium), engineering plastics (PEEK, nylon, ABS), and composites—all of which are commonly used in final production. At Sunmy, we help clients select the right material for their prototypes: for instance, when a client developing an industrial sensor needed a heat-resistant prototype, we recommended CNC-machining PEEK (a high-performance plastic) instead of 3D printing, as PEEK 3D prints are prone to warping and lack the same heat resistance as machined PEEK.

3D printing is limited to materials like PLA, ABS, resin, and a small selection of metal powders. While these work for early-stage prototypes, they often can’t replicate the properties of production-grade materials. For example, a 3D printed ABS prototype will be less impact-resistant than a CNC-machined ABS prototype, leading to misleading test results.

3. Budget and Batch Size

For small batch sizes (1–5 prototypes), 3D printing can be more cost-effective—especially for simple plastic parts—since it requires no custom tooling. However, as batch sizes increase (10+ prototypes), CNC machining becomes more economical. Sunmy’s CNC machines are optimized for low-volume prototyping: we avoid the high tooling costs associated with mass production, and our automated processes reduce labor time. A client in the electronics industry recently needed 20 prototypes of a brass connector: 3D printing would have cost ~$40 per part, while our CNC machining service delivered them for ~$25 per part—with better precision and material quality.

It’s also important to factor in “hidden costs”: 3D printed prototypes often require post-processing (sanding, painting, or curing) to improve finish, which adds time and expense. CNC-machined prototypes typically need minimal post-processing, saving you money in the long run.

4. Production Speed

3D printing is faster for simple, small prototypes: a basic plastic part can be printed overnight. But for complex or large prototypes—especially those made from metal—CNC machining is often quicker. For example, a client needed a 10cm x 15cm aluminum prototype with multiple holes and grooves. A 3D printer would have taken 12+ hours to print the part, plus 4 hours of post-processing; our 5-axis CNC machine completed the same prototype in 3 hours, with no additional finishing needed.

Sunmy’s in-house equipment further speeds up CNC prototyping: our 5-axis machines can machine multiple sides of a prototype in one setup, eliminating the need to reposition the part and reducing lead times by up to 50%. We also keep common materials (aluminum, stainless steel, ABS) in stock, so we can start your prototype as soon as we receive your design.

How Sunmy Helps Clients Choose (and Execute) the Right Prototype Method

As a precision hardware manufacturer with 工贸一体 (industrial-trade integrated) capabilities, we don’t just offer CNC machining—we help clients navigate the entire prototype development process. Here’s how we support your project:

Step 1: Design Review and Consultation

First, our engineering team reviews your design (CAD file, 3D model, or sample) and discusses your goals: What will the prototype be used for (testing, investor pitches, fit checks)? What material will the final part use? What’s your timeline and budget? Based on this, we recommend either CNC machining or 3D printing (and if needed, connect you with trusted 3D printing partners for plastic prototypes).

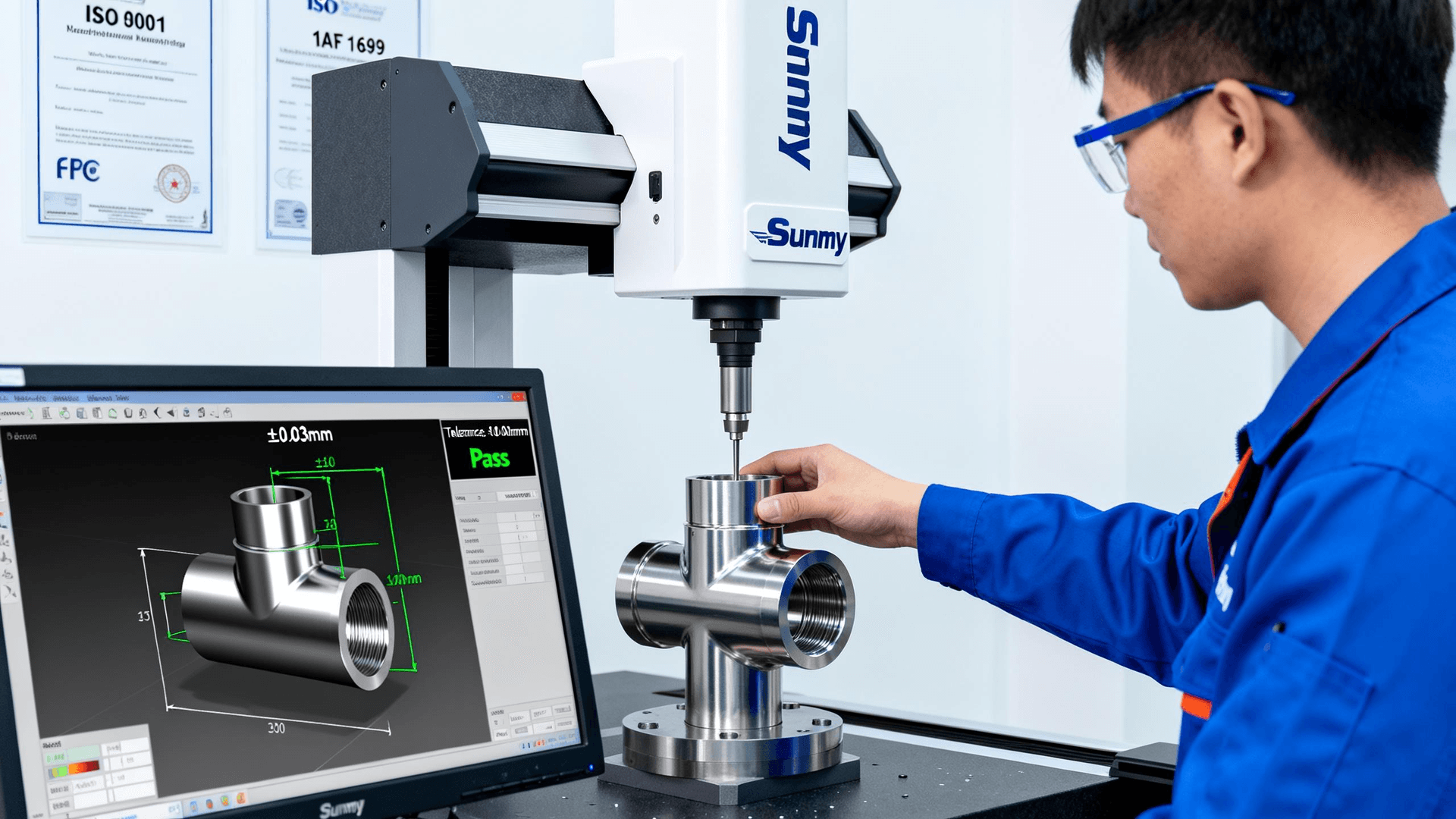

Step 2: Prototype Production with Rigorous Quality Checks

If CNC machining is the right fit, we use our advanced equipment to produce your prototype. Our quality control process starts before production: we run dry tests of the CNC program to catch errors. During machining, we use CMMs and laser scanners to verify dimensions in real time.

After production, every prototype undergoes a final inspection—we check surface finish, tolerances, and functional performance (e.g., fit with other parts) and share a detailed QC report with you.

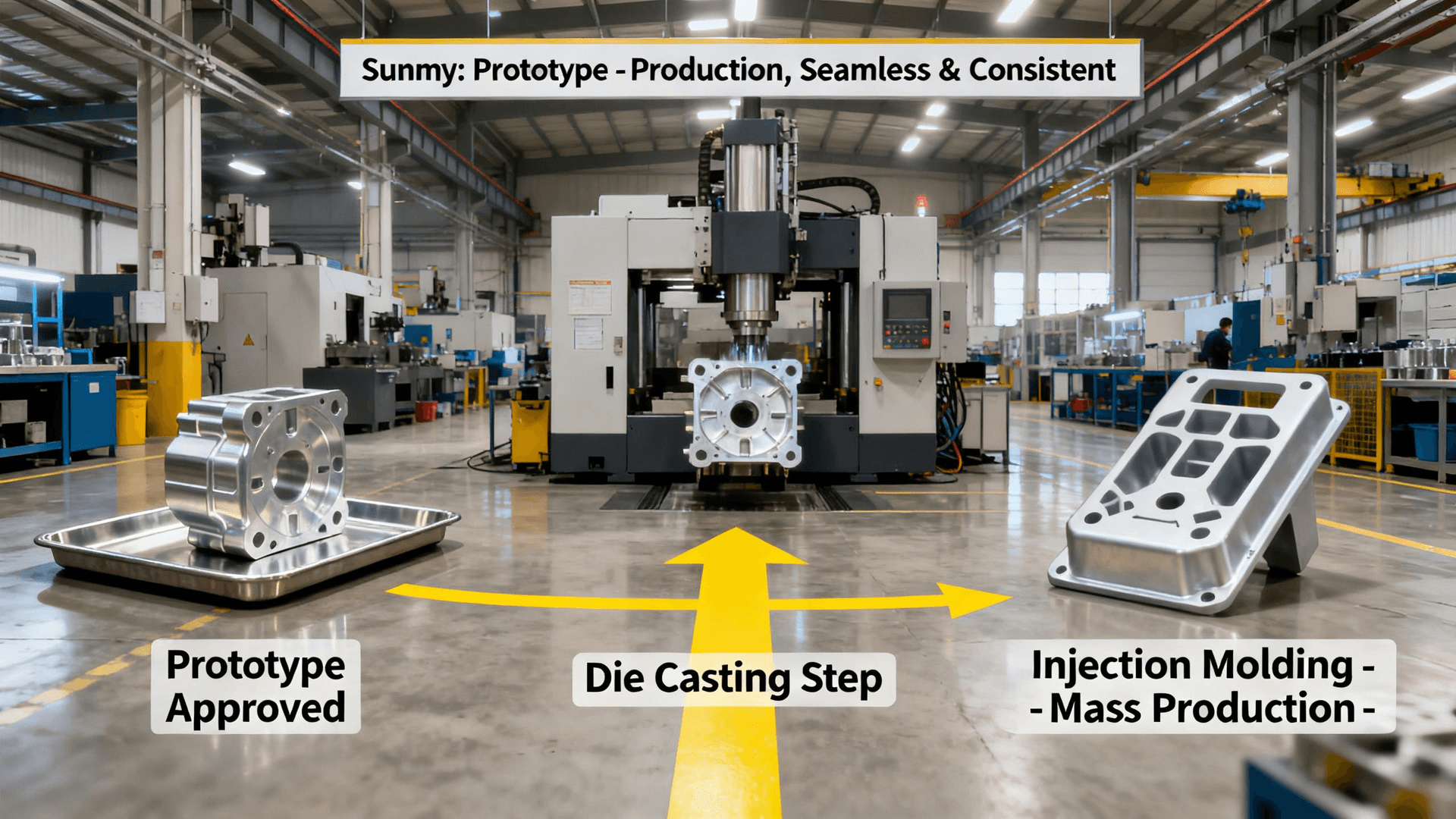

Step 3: From Prototype to Production

One of Sunmy’s biggest advantages is our ability to scale from prototypes to mass production. If your CNC-machined prototype passes testing, we can seamlessly transition to full-scale manufacturing—using the same equipment and quality standards. We also offer complementary services like die casting (for metal parts) and custom injection molding (for plastic parts), so you don’t have to work with multiple suppliers. A recent client started with 10 CNC-machined prototypes of a plastic housing; after testing, we switched to custom injection molding for 10,000 production parts—saving them time and ensuring consistency between prototype and final product.

Real Client Story: CNC Machining Solving a 3D Printing Prototype Failure

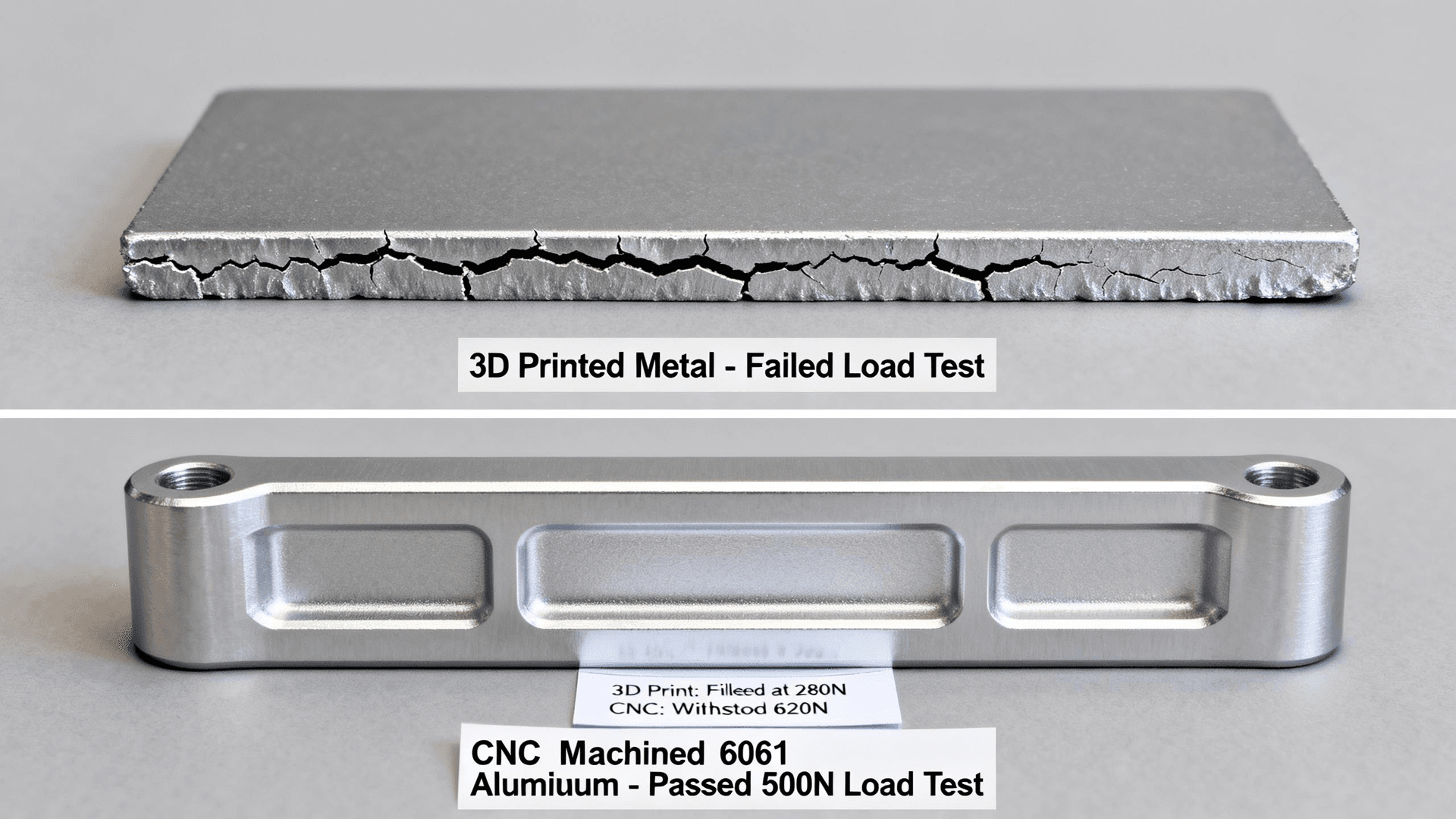

A North American automotive supplier came to Sunmy after struggling with 3D printed prototypes for a lightweight aluminum suspension component. Their 3D printed parts (using metal powder) were brittle and failed load tests—plus, each part cost $150 and took 3 days to produce.

They needed a prototype that would mimic the strength and weight of the final CNC-machined part, with a 1-week timeline.

Our team recommended CNC machining using 6061 aluminum (the same material as the final part). We optimized their CAD design to reduce machining time, then used our 5-axis CNC machine to produce 5 prototypes in 2 days. Each prototype cost $80 (47% less than 3D printing) and passed all load tests—with tolerances of ±0.004mm, ensuring a perfect fit with other suspension components. The client was so satisfied that they now use Sunmy for both prototypes and mass production, including die casting for other automotive parts.

When to Partner with a CNC Machining China Provider Like Sunmy

Choose CNC machining for your prototype if:

- You need tight tolerances (±0.1mm or smaller) or a smooth surface finish.

- Your prototype material must match production-grade metals or engineering plastics.

- You need 10+ prototypes, or the prototype requires structural strength for testing.

- You want to seamlessly scale from prototype to mass production.

Choose 3D printing if:

- You’re creating a conceptual model or early-stage ergonomic test (not functional testing).

- Your prototype is small, simple, and made from plastic.

- You need 1–5 prototypes with an extremely fast turnaround (24–48 hours).

At Sunmy, we’re not just a CNC Machining China service provider—we’re your partner in prototype development. Our team has 8+ years of experience helping global clients avoid common pitfalls (like choosing the wrong technology) and deliver high-quality prototypes on time. To learn more about our team and our commitment to precision, visit our About Us page. If you’re ready to start your prototype project—or need help deciding between CNC machining and 3D printing—reach out via our Contact Us page for a free consultation. We’ll work with you to turn your design into a prototype that sets your product up for success.