Custom Injection Molding for Industrial Products: A Complete Guide to Precision Solutions by Sunmy Hardware

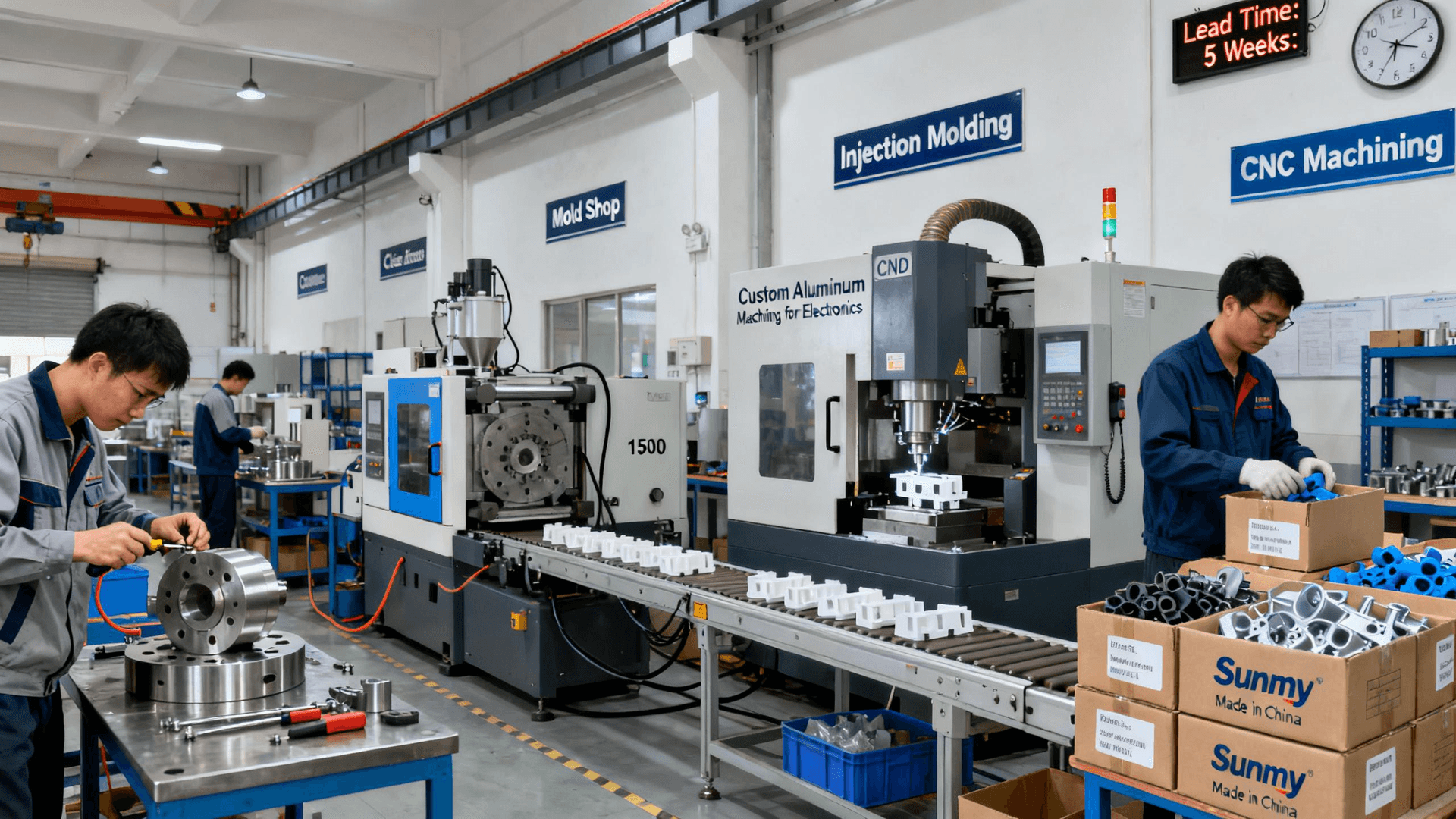

In the fast-paced world of industrial manufacturing, finding a reliable partner for custom injection molding for industrial components can make or break your production timeline and product quality. For over seven years, Shenzhen Sunmy Hardware Co., Ltd.—a leading custom parts manufacturer in China founded in 2016—has specialized in turning complex client requirements into high-precision plastic components. Our 工贸一体 (industrial-trading integrated) model combines in-house manufacturing capabilities (including Casting, Lathe, Machining, Stamping, and Injection Molding) with robust mold development expertise, allowing us to deliver end-to-end injection molding solutions that meet the unique needs of clients across industries. Whether you provide a detailed drawing, a physical sample, or just a concept for your industrial part, our team transforms ideas into tangible, durable products. In this guide, we’ll break down everything you need to know about custom injection molding for industrial applications, from the core process to real-world use cases—and how Sunmy’s capabilities set us apart.

1. What Is Custom Injection Molding for Industrial Products?

Custom injection molding is a manufacturing process that injects molten plastic into a precision-engineered mold, where it cools, solidifies, and takes the shape of the mold cavity. Unlike mass-produced off-the-shelf parts, this method is tailored to create components that fit specific industrial requirements—whether that means unique dimensions, high-temperature resistance, or compatibility with other mechanical parts.

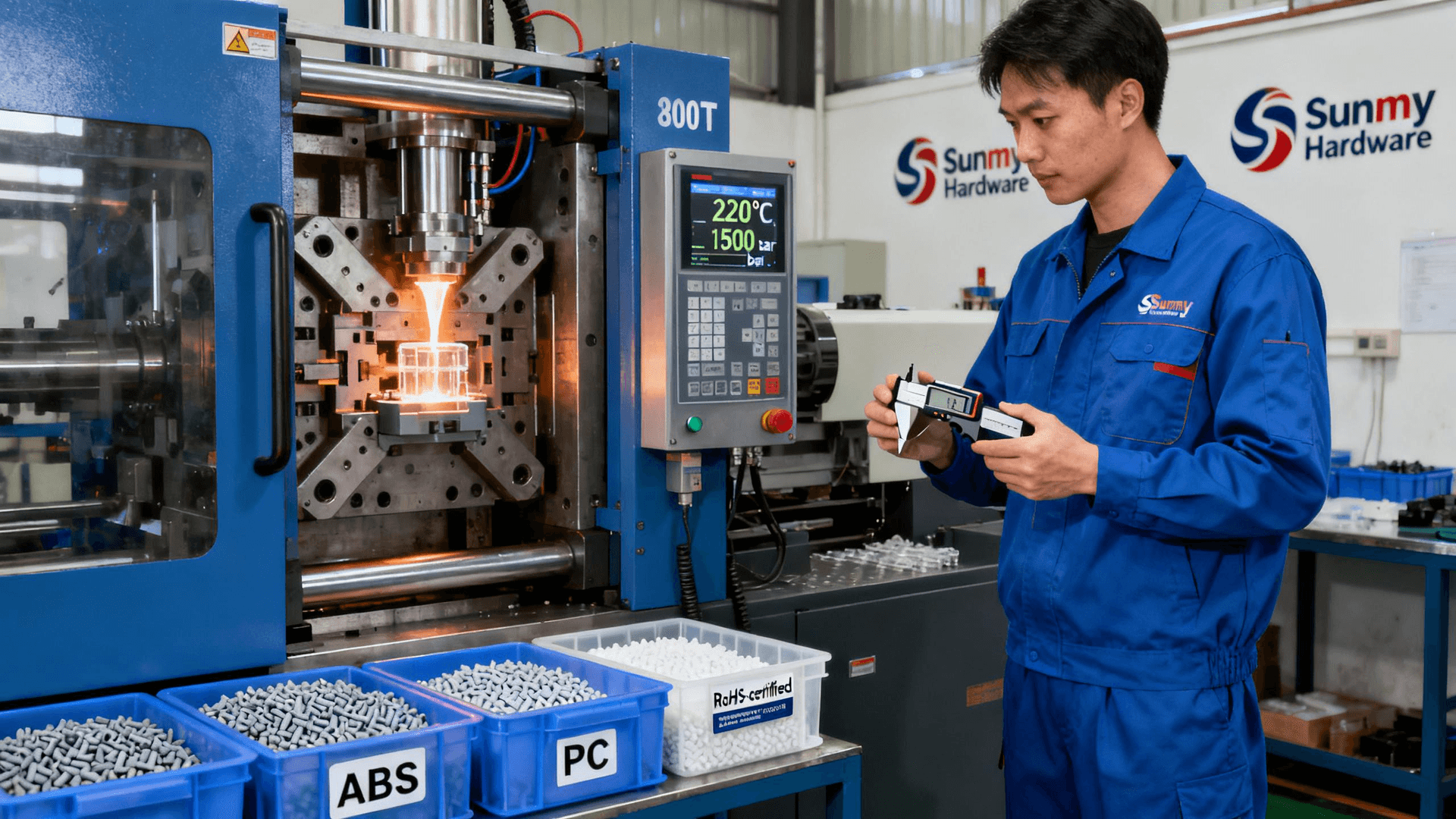

At Sunmy, we don’t just “do” injection molding: we integrate it with our full suite of manufacturing services to solve complex challenges. For example, if a client needs a plastic housing for a medical device that also requires metal inserts (a common need in precision machining for medical equipment parts), our team coordinates injection molding with CNC machining to embed inserts seamlessly—eliminating the need for third-party suppliers and reducing lead times. Our machines (ranging from 50T to 300T clamping force) handle a wide range of thermoplastics, including ABS, PC, PP, and nylon, ensuring we can match the material properties your industrial application demands (e.g., chemical resistance for automotive components or biocompatibility for medical parts).

2. Key Applications: Where Industrial Injection Molding Shines

Custom injection molding is versatile—but it truly excels in industries where precision, consistency, and durability are non-negotiable. Below are the sectors where Sunmy’s clients rely on our injection molding solutions for plastic parts most frequently:

Automotive Components Customization

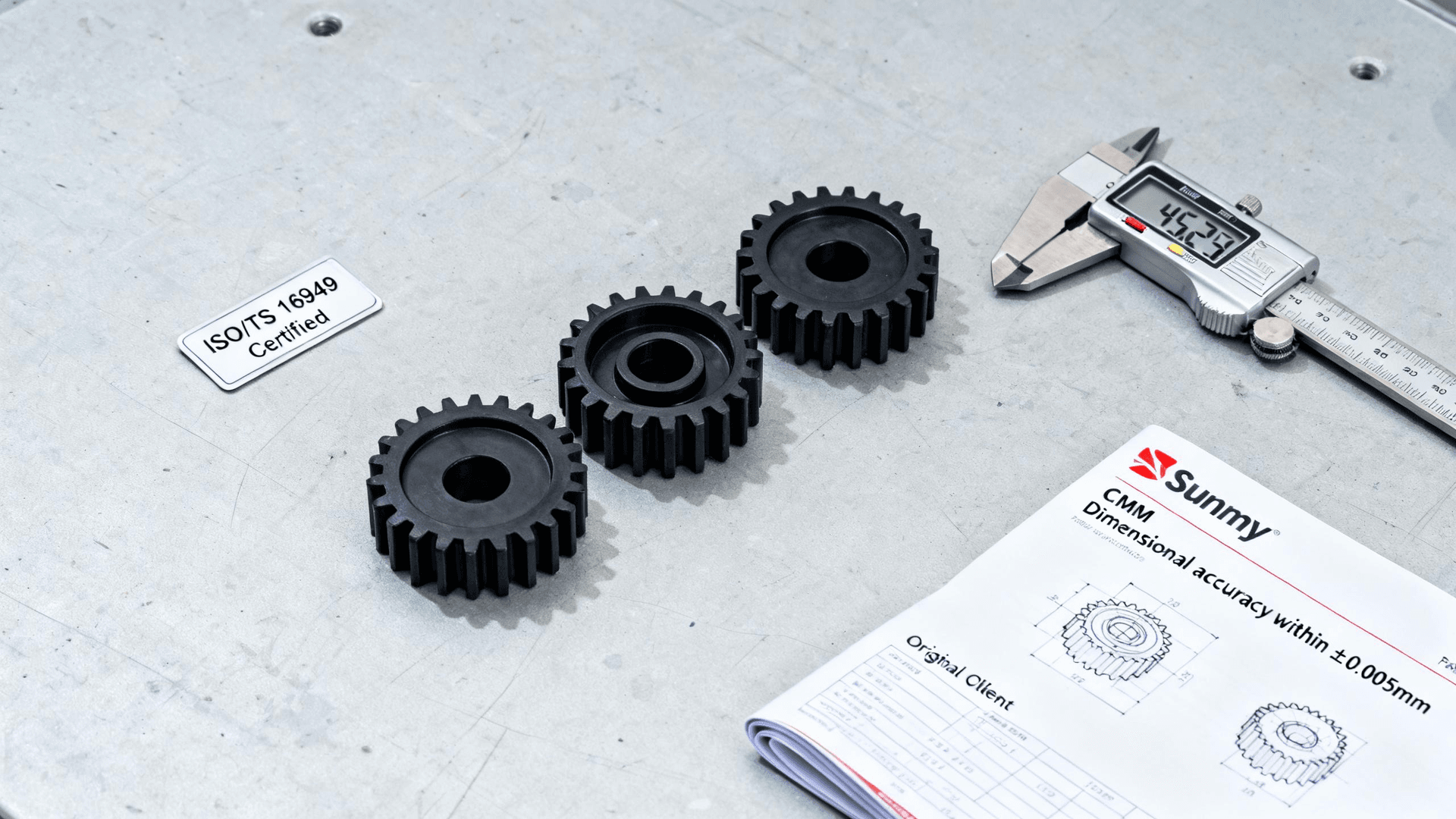

The automotive industry demands parts that withstand vibration, extreme temperatures, and constant use. Sunmy produces custom injection-molded components like sensor housings, interior trim brackets, and under-hood plastic clips—all engineered to meet ISO/TS 16949 standards. For one European automotive supplier, we developed a heat-resistant plastic connector that replaced a heavier metal part, cutting their vehicle weight (and fuel costs) while maintaining structural integrity.

Electronics & Electrical Components

As a custom electronic components manufacturer, we understand that electronics require parts with tight tolerances (often ±0.01mm) to fit circuit boards and wiring. Our injection molding process creates precision plastic enclosures for IoT devices, cable management clips, and battery holders—many of which are paired with our custom aluminum machining parts for electronics to create fully integrated solutions.

Medical Equipment

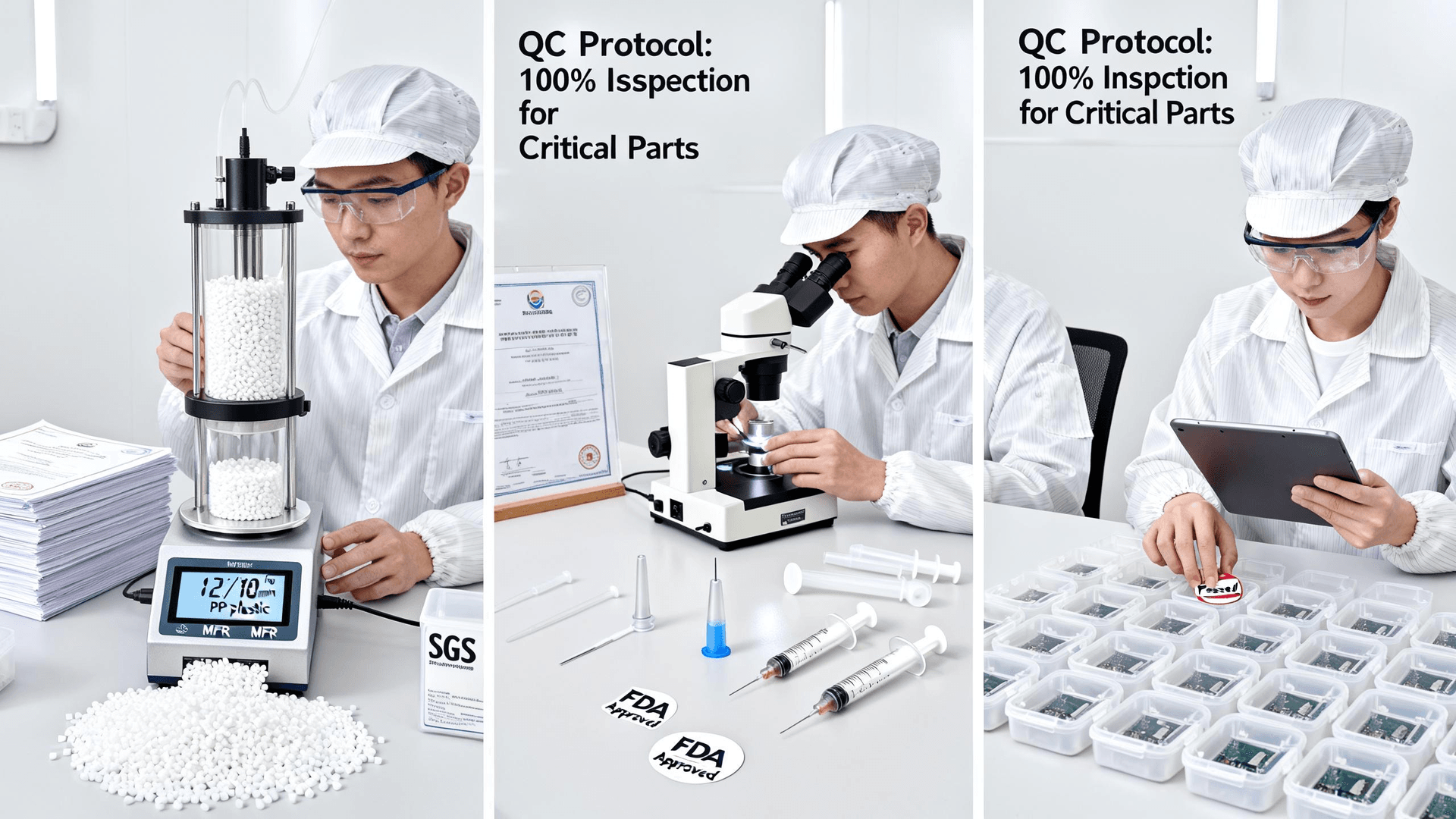

Medical devices need parts that are not only precise but also sterile and biocompatible. Sunmy’s cleanroom-compatible injection molding lines produce components like syringe plungers, diagnostic device casings, and surgical tool handles, all tested to meet FDA and CE standards. Our quality control team uses laser measurement tools to ensure every part adheres to the strictest medical specifications.

3. Sunmy’s Mold Development Process: The Foundation of Precision

Great injection molding starts with great 模具 (molds)—and this is where Sunmy’s expertise truly stands out. Our mold development capabilities are designed to turn your design into a production-ready tool that delivers consistent results, even for high-volume runs. Here’s our step-by-step approach:

1.Needs Analysis & Design Review: First, our engineering team collaborates with you to review your drawing, sample, or concept. We identify potential challenges (e.g., thick sections that could cause warping) and suggest design optimizations to improve manufacturability—saving you time and cost down the line. For example, when a U.S. client requested USA custom hardware parts with a complex undercut, we adjusted the mold design to use a sliding core, eliminating the need for post-production trimming.

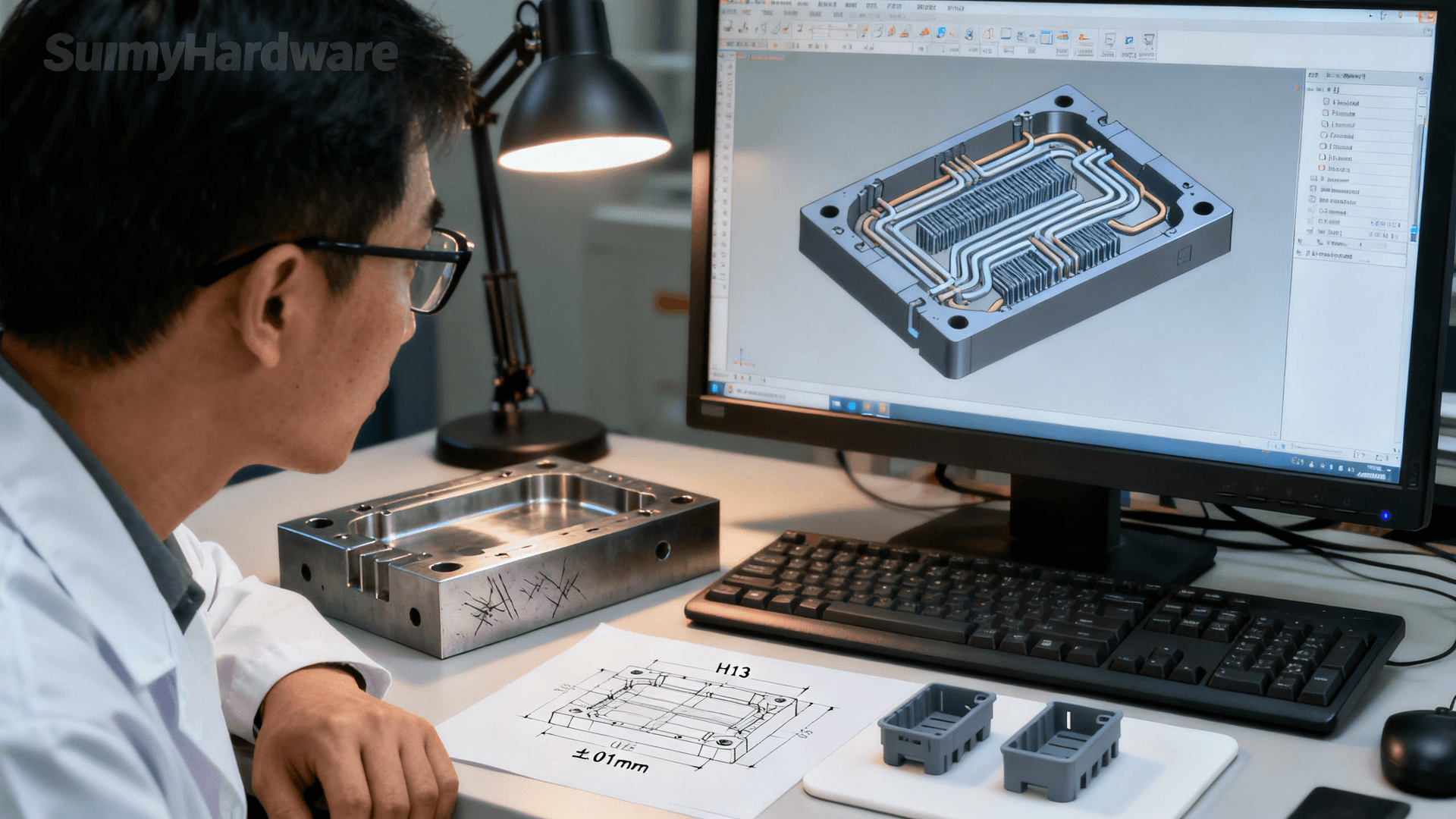

2.Mold Design & Fabrication: Using CAD/CAM software (SolidWorks, AutoCAD), we design the mold with precision, including cooling channels (to ensure uniform cooling) and gating systems (to control plastic flow). We fabricate molds in-house using high-grade steel (H13 or S7) for durability—critical for long production runs (some of our molds have produced over 1 million parts without wear).

3.Prototype & Test Molding: Before full production, we run a small batch of prototypes to validate the mold. We inspect each prototype for dimensional accuracy, surface finish, and material performance, making adjustments to the mold if needed. This iterative process ensures that when we scale to mass production, there are no surprises.

4.Mass Production & Quality Checks: Once the mold is approved, we move to full-scale production. Our team monitors every run in real time, and every part undergoes rigorous testing (more on that below). The best part? Because we handle mold development and production in-house, we control every step—no delays from outsourcing to third-party mold makers.

4. Real-World Success: Sunmy’s Injection Molding Case Study

Actions speak louder than words—and our client success stories highlight how our one-stop production model solves real problems. Here’s a recent example:

A U.S.-based industrial equipment manufacturer needed a custom plastic gear housing for their conveyor system. Their previous supplier struggled with inconsistent wall thickness (leading to housing cracks) and long lead times (up to 12 weeks). They turned to Sunmy for a solution.

- First, our team analyzed their 3D model and identified that the original design had uneven cooling zones. We suggested a minor adjustment to the housing’s rib structure to improve heat distribution.

- We developed a prototype mold in 4 weeks (half the time of their previous supplier) and produced 50 test housings. The client confirmed the parts fit perfectly and withstood their load tests.

Case Product and detection scenarios - We scaled to mass production, delivering 10,000 housings in 6 weeks—with zero defects. The client now uses Sunmy for all their custom plastic and metal parts (including custom lathe parts according to drawing), reducing their overall supply chain costs by 20%.

5. Quality You Can Trust: Sunmy’s Testing Protocols

For industrial parts, quality isn’t an option—it’s a requirement. At Sunmy, we’ve built a rigorous quality control (QC) process to ensure every part meets or exceeds your specifications:

- Raw Material Inspection: All plastics are tested for purity and consistency (e.g., melt flow rate, impact resistance) before they enter our machines. We only use materials from certified suppliers (with SGS or RoHS certifications).

- In-Process Testing: During production, our team takes random samples every 30 minutes to check dimensions (using coordinate measuring machines, or CMMs, for accuracy) and surface finish (using optical comparators).

- Final Inspection: Every batch undergoes a 100% visual inspection for defects (e.g., burrs, sink marks) and functional testing (e.g., load testing for structural parts, leak testing for sealed components).

- Documentation: We provide a full QC report with every order, including test results and material certificates—critical for industries like automotive and medical that require traceability.

6. Why Choose Sunmy for Your Custom Injection Molding Needs?

There are many injection molding suppliers—but Sunmy’s combination of expertise, capabilities, and service makes us a partner, not just a vendor:

- One-Stop Production: We handle everything from mold development to injection molding to post-processing (e.g., CNC machining, assembly). No need to manage multiple suppliers—we simplify your supply chain.

One-stop production panorama - Proven Expertise: With over 7 years in industrial manufacturing, we understand the unique challenges of sectors like automotive, electronics, and medical. Our team includes 15+ engineers with specialized experience in mold design and injection molding.

- Speed & Flexibility: We offer fast lead times (4–6 weeks for mold development, 2–4 weeks for production) and can accommodate small batches (as low as 100 parts) or large volumes (100,000+ parts).

- Global Reach: As a custom parts manufacturer in China with experience serving clients in the U.S., Europe, and Asia, we understand international standards (ISO, FDA, CE) and can handle shipping and logistics to your door.

Conclusion

Custom injection molding is a powerful tool for industrial manufacturers—but it only works if you have the right partner. At Sunmy Hardware, our custom injection molding for industrial components is backed by decades of combined expertise, in-house mold development, and a commitment to quality. Whether you need injection molding solutions for plastic parts, automotive components customization, or a mix of plastic and metal parts (like aluminum die casting parts paired with plastic enclosures), we have the capabilities to deliver.

To learn more about our team and manufacturing facilities, visit our About Us page. To see our full range of services—including CNC machining, stamping, and die casting—check out our Production Capability page. Ready to start your project? Contact Us today, and our engineering team will help you turn your design into a high-quality, cost-effective product.

At Sunmy, we don’t just make parts—we make your production process easier.