Enhance Durability and Performance with Aluminum Die Casting Parts

In today’s fast-paced manufacturing landscape, industries ranging from automotive to electronics demand components that balance durability, precision, and cost-effectiveness. Among the most reliable solutions to meet these needs is aluminum die casting—a process that transforms molten aluminum into high-performance parts tailored to strict specifications. For businesses seeking to elevate their end products, partnering with a trusted aluminum die casting parts supplier is critical. As a leading 工贸 (industry-trade) integrated foreign trade company based in Shenzhen, China, Shenzhen Sunmy Hardware Co.,Ltd. (established in 2016) specializes in delivering custom aluminum die casting parts and comprehensive machining solutions that enhance both durability and performance.

Why Aluminum Die Casting Boosts Durability & Performance

Aluminum’s inherent properties—combined with advanced die casting techniques—make it a superior choice for high-demand applications:

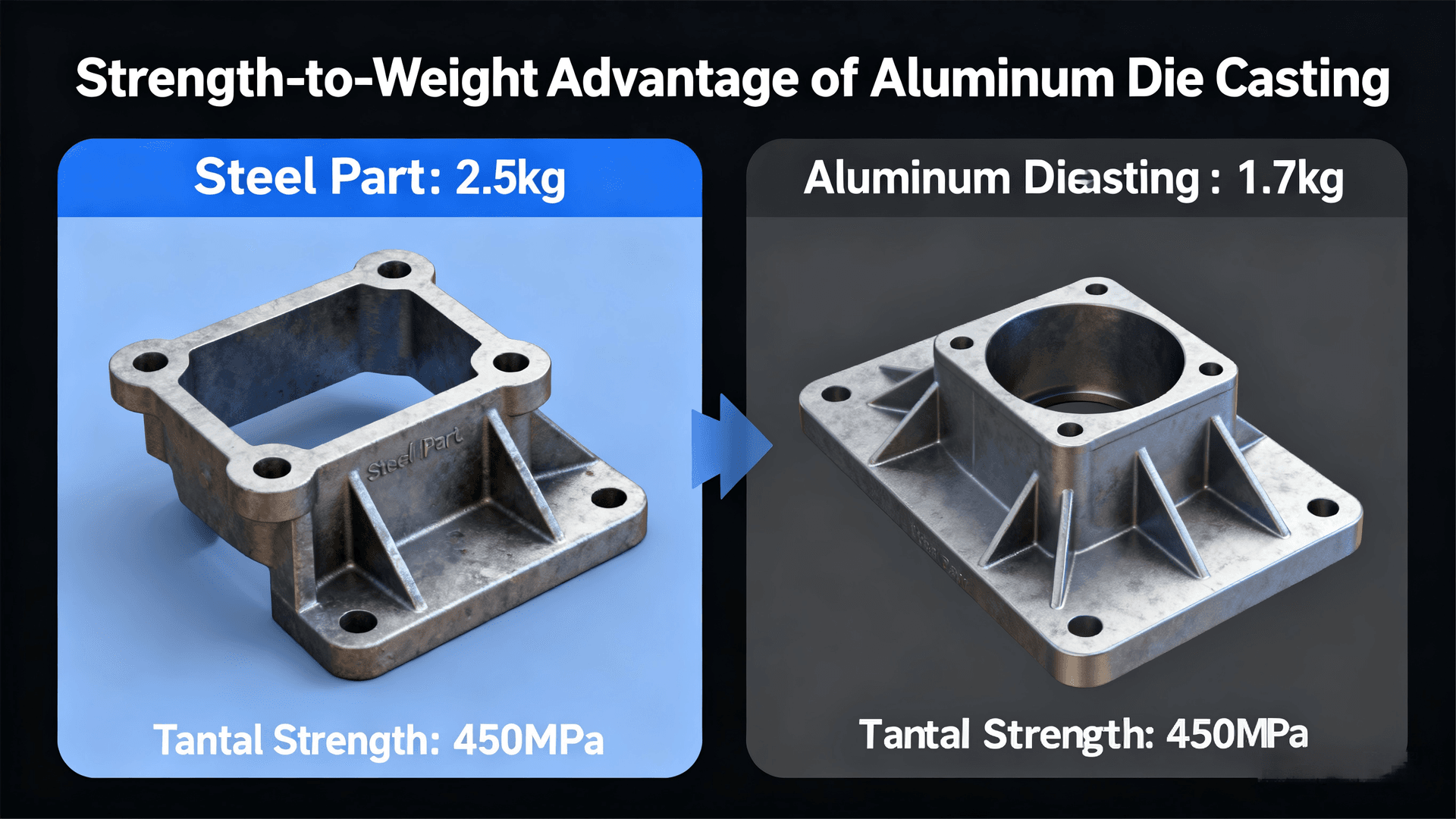

1.Exceptional Strength-to-Weight Ratio: Aluminum die casting parts are 30% lighter than steel equivalents while maintaining impressive tensile strength, reducing wear on assembled products and improving energy efficiency (critical for automotive components customization).

2.Corrosion Resistance: Aluminum forms a natural oxide layer, eliminating the need for extra coatings in many environments. This extends part lifespan, especially for outdoor or industrial use cases (e.g., industrial parts supplier applications).

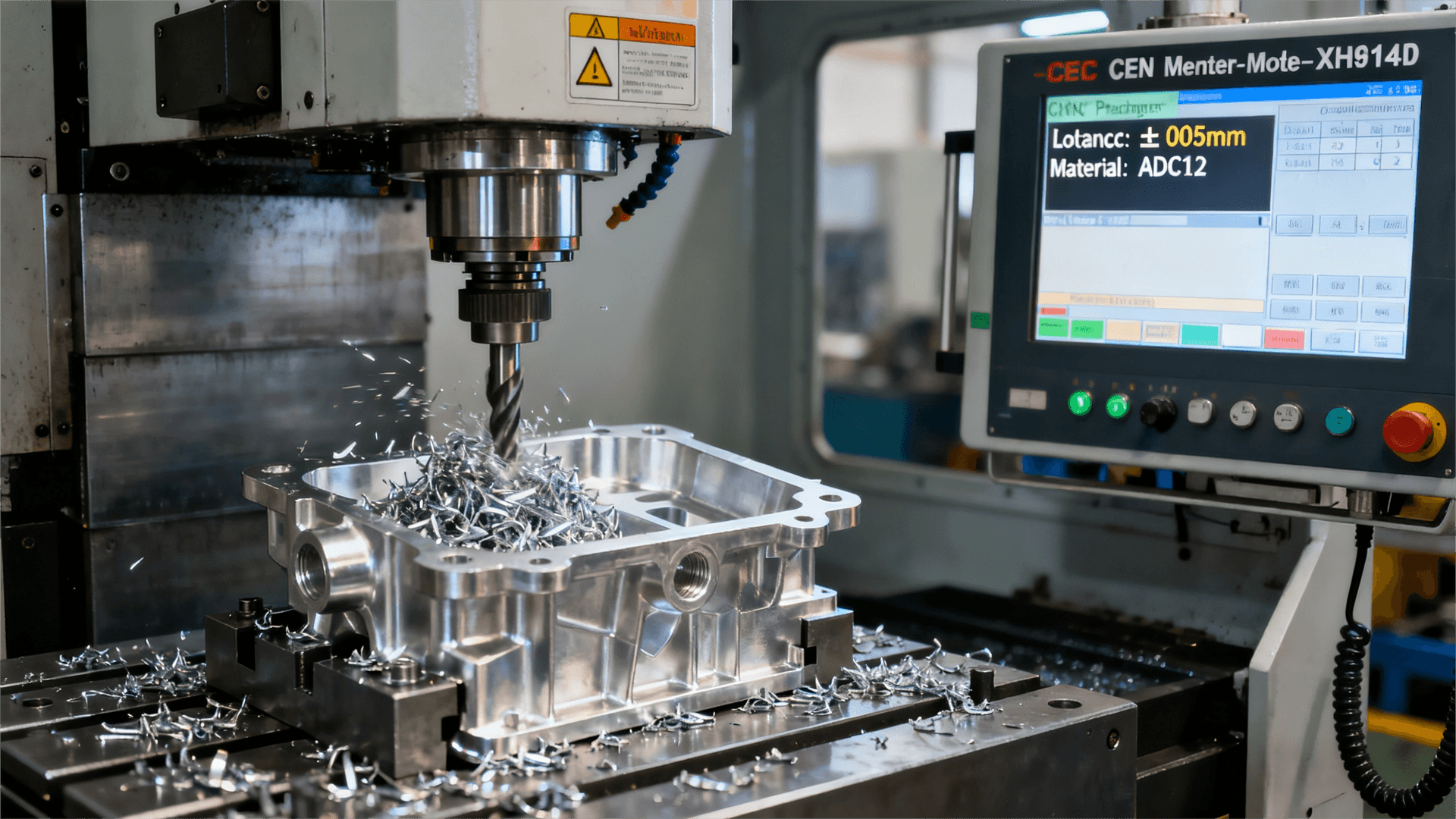

3.Precision & Consistency: Modern die casting processes (paired with our CNC machining service) achieve tight tolerances (up to ±0.005mm), ensuring parts fit seamlessly into complex assemblies. This consistency minimizes failure risks in high-stress scenarios, such as precision machining for medical equipment parts.

4.Design Flexibility: Unlike traditional manufacturing, aluminum die casting supports intricate geometries—from thin walls to complex cavities. This allows engineers to optimize part design for performance without compromising durability, a key advantage for custom electronic components manufacturer projects.

Sunmy Hardware: Your Partner for High-Performance Aluminum Die Casting

At Shenzhen Sunmy Hardware Co.,Ltd., we don’t just supply aluminum die casting parts—we deliver end-to-end solutions tailored to your unique needs. Our strength lies in:

1. Comprehensive Production Ecosystem

We boast a full suite of manufacturing capabilities to support every stage of your project:

- Casting: High-pressure aluminum die casting for mass-produced parts.

- Machining: Advanced CNC machining service for post-casting precision (ideal for custom aluminum machining parts for electronics).

- Lathe & Stamping: Specialized in custom lathe parts according to drawing and stamping service for stainless steel brackets—ensuring compatibility with your existing designs.

- Injection Molding: Complementary injection molding solutions for plastic parts and injection molding for industrial components—enabling one-stop sourcing for multi-material assemblies.

2. Industry-Leading Customization Expertise

As a top custom parts manufacturer in China, we thrive on turning complex requirements into reality. Whether you need USA custom hardware parts (compliant with ANSI/ASME standards), custom metal parts for harsh environments, or custom spare parts for legacy equipment, our team works closely with you to:

- Analyze your drawings, samples, or performance goals.

- Optimize designs for die casting feasibility (reducing material waste and cost).

- Conduct prototype testing to validate durability and performance.

3. Rigorous Quality Control

Durability starts with quality. Our processes include:

- Material inspection (using high-purity aluminum alloys like ADC12 and A380).

- In-line testing (dimensional checks, pressure testing for leak-prone parts).

- Post-production audits (salt spray testing for corrosion resistance, tensile strength analysis).

This commitment ensures our parts meet ISO 9001 and IATF 16949 standards—critical for automotive components customization and precision plastic components used in medical devices.

Real-World Applications: Where Our Aluminum Die Casting Shines

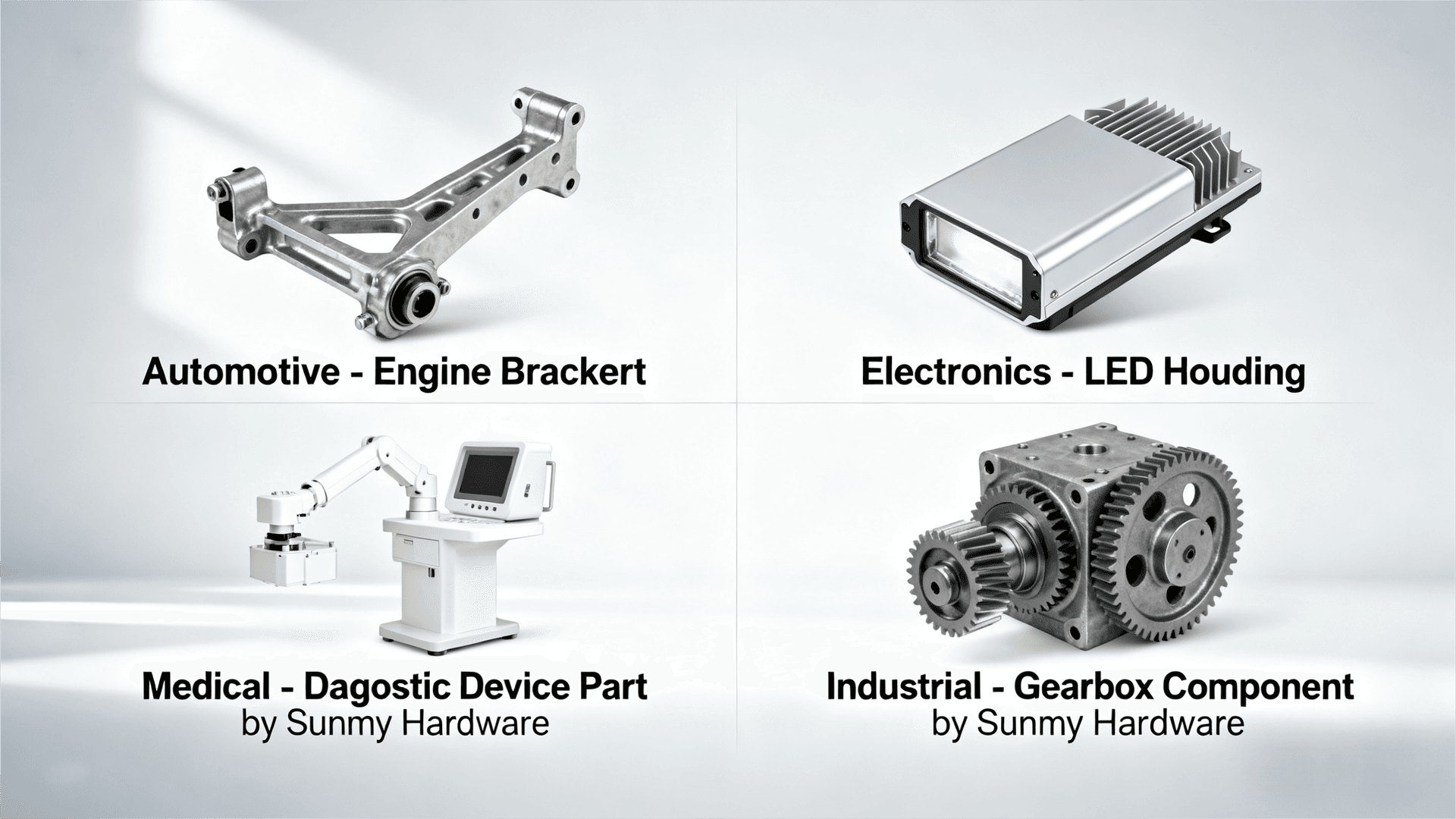

Our parts enhance durability and performance across industries:

- Automotive: Lightweight die casting brackets (reducing vehicle weight by 15%) and heat sinks (improving engine cooling efficiency).

- Electronics: Custom aluminum machining parts for electronics (e.g., LED housing, server chassis) that resist thermal expansion and electromagnetic interference.

- Medical: Precision machining for medical equipment parts (e.g., diagnostic device enclosures) that meet biocompatibility and sterilization requirements.

- Industrial: Heavy-duty die casting gears and housings for machinery—withstand 10,000+ hours of continuous operation.

Start Enhancing Your Products Today

If you’re ready to upgrade to aluminum die casting parts that deliver long-lasting durability and peak performance, Shenzhen Sunmy Hardware Co.,Ltd. is your trusted partner. We serve global clients—from small businesses to Fortune 500 companies—with timely delivery (average lead time: 2–4 weeks for prototypes, 4–6 weeks for mass production) and competitive pricing.

Explore our full range of services:

- Aluminum die casting parts supplier

- OEM machining parts

- Custom lathe parts manufacturer

- Injection molding solutions

Visit our website at sunmyhardware.com to submit your project details, download our catalog, or contact our engineering team. Let’s build parts that outperform expectations—together.

Shenzhen Sunmy Hardware Co.,Ltd. – Precision in Every Cast, Durability in Every Part.