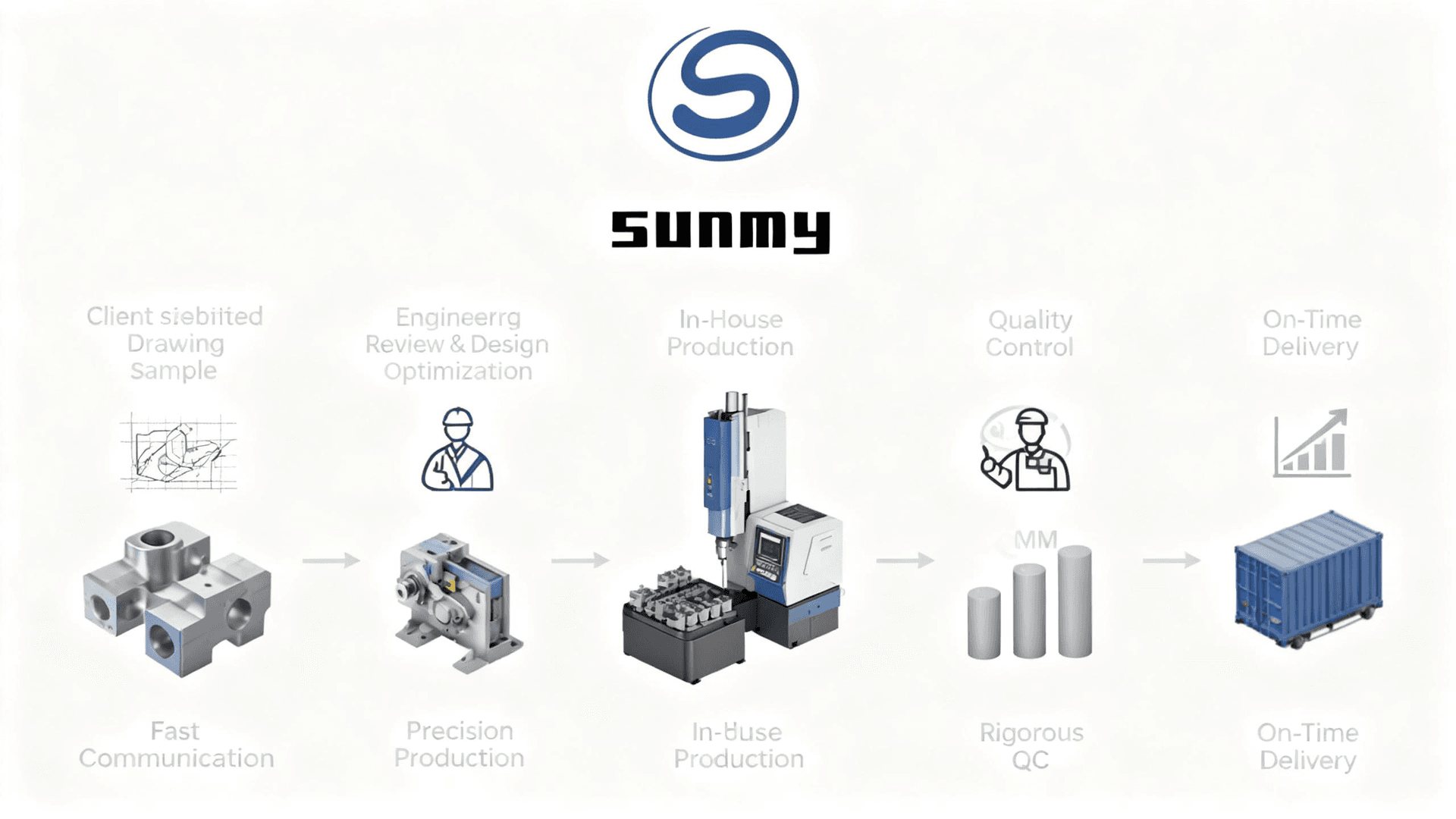

From Drawing to Delivery: Sunmy Hardware – Your Trusted China Custom Hardware Manufacturer for OEM Metal Parts

When it comes to bringing your custom designs to life, finding a reliable custom parts manufacturer in China that balances precision, speed, and flexibility can feel like a challenge. Whether you need USA custom hardware parts, automotive components customization, or precision machining for medical equipment parts, the gap between a concept on paper and a high-quality finished product often hinges on communication, engineering expertise, and production capability. At Shenzhen Sunmy Hardware Co., Ltd. – founded in 2016 as a leading 工贸一体 (industrial and trade integrated) OEM/ODM manufacturer – we’ve streamlined the process from drawing to delivery, turning complex custom requests into seamless success stories for global clients. As your trusted China supplier and custom hardware manufacturer, we specialize in translating your ideas, drawings, or samples into durable, precise custom metal parts, plastic components, and industrial solutions that meet even the strictest industry standards.

The Custom Parts Challenge: Why Communication & Expertise Matter

For engineers, product managers, and buyers worldwide, the biggest pain points in custom manufacturing often boil down to three things: misaligned expectations due to poor communication, compromised precision in production, and delayed deliveries that derail project timelines. When you’re sourcing OEM machining parts or custom lathe parts according to drawing, you need a partner who doesn’t just “make parts” – but understands your industry, anticipates challenges, and collaborates with you every step of the way.

At Sunmy Hardware, we built our business on solving these exact problems. Our professional engineering team and fast communication protocols ensure no detail is lost in translation, while our integrated production system (Casting, Lathe, Machining, Stamping, Injection Molding) gives us the flexibility to handle everything from aluminum die casting parts to precision plastic components. Whether you’re a U.S. company needing USA custom hardware parts or a medical device manufacturer seeking precision machining for medical equipment parts, we turn your unique requirements into reality – on time, on spec, and on budget.

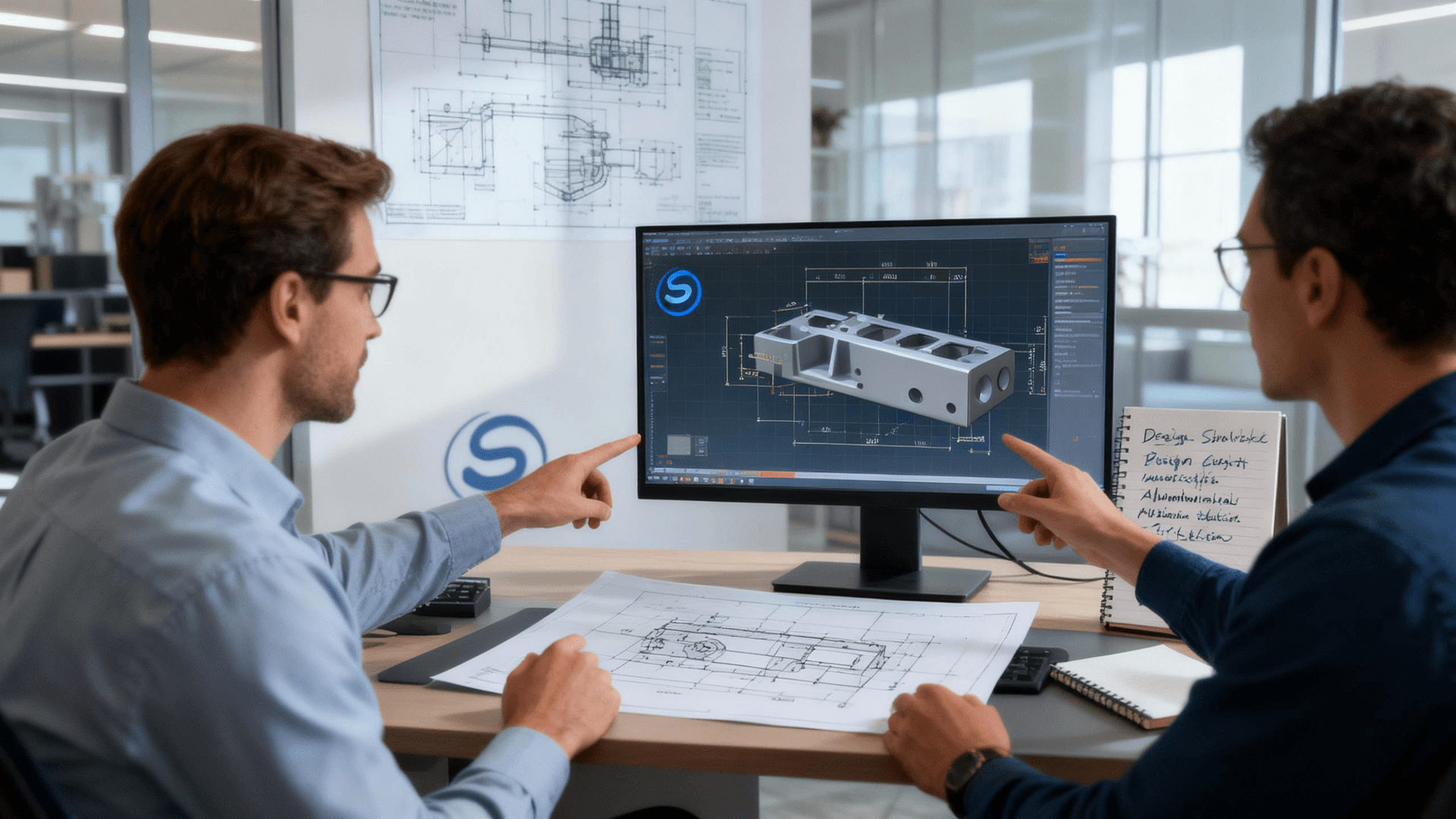

Step 1: From Drawing to Design – Collaborative Engineering & Fast Communication

The journey begins with your vision – and we make sure it’s heard loud and clear. Unlike generic suppliers who treat drawings as static instructions, our team sees them as the starting point of a partnership. Whether you submit a 2D sketch, 3D model (SolidWorks, AutoCAD, or STEP files), or even a physical sample, our professional engineering team dives in to:

- Validate design feasibility for production (e.g., optimizing wall thickness for injection molding solutions for plastic parts or adjusting tolerances for CNC machining service).

- Recommend cost-effective materials (aluminum, stainless steel, plastic, or specialty alloys) tailored to your application – whether it’s custom aluminum machining parts for electronics or stamping service for stainless steel brackets.

- Address potential manufacturing challenges upfront, saving you time and rework later.

Take our recent collaboration with a U.S.-based electronics firm: they needed custom electronic components manufacturer for a new device, with tight tolerances and a 6-week lead time. After receiving their 3D model, our engineers identified a design tweak that would improve durability without increasing cost – all within 24 hours of initial contact. That’s the power of fast communication and engineering expertise: we don’t just follow instructions – we elevate your design.

This stage is where keywords like custom lathe parts according to drawing, custom parts manufacturer in China, and OEM metal parts come to life – because every project starts with understanding your unique needs and translating them into a manufacturable plan.

Design Collaboration & Engineering Review(

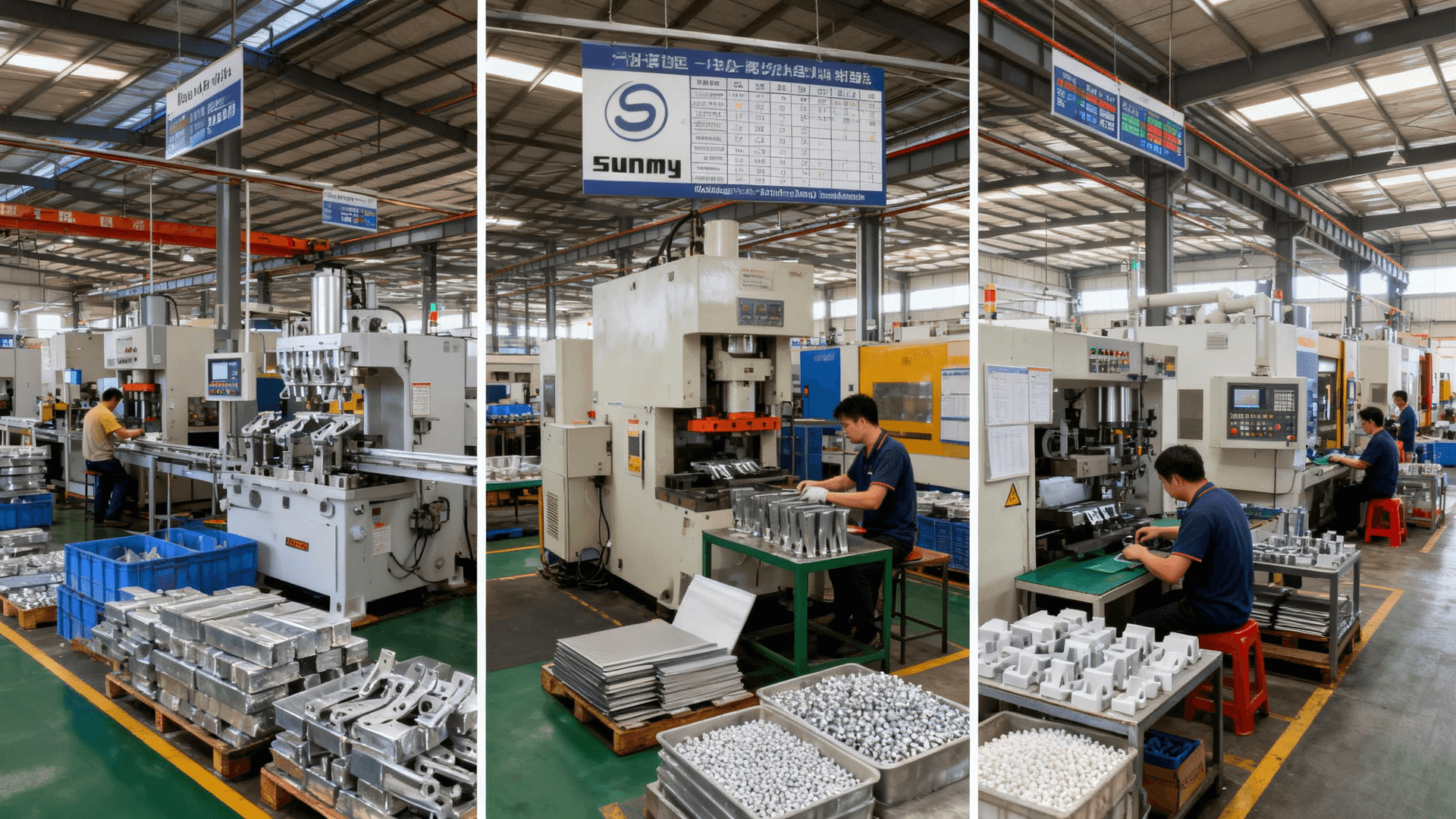

Step 2: Precision Production – Our Integrated Manufacturing Capabilities

Once the design is finalized, we move to production – and our comprehensive in-house capabilities set us apart from other industrial parts suppliers. Unlike suppliers who outsource key processes, Sunmy owns and operates a full suite of equipment, giving us complete control over quality, lead times, and costs. Here’s how we handle different custom needs:

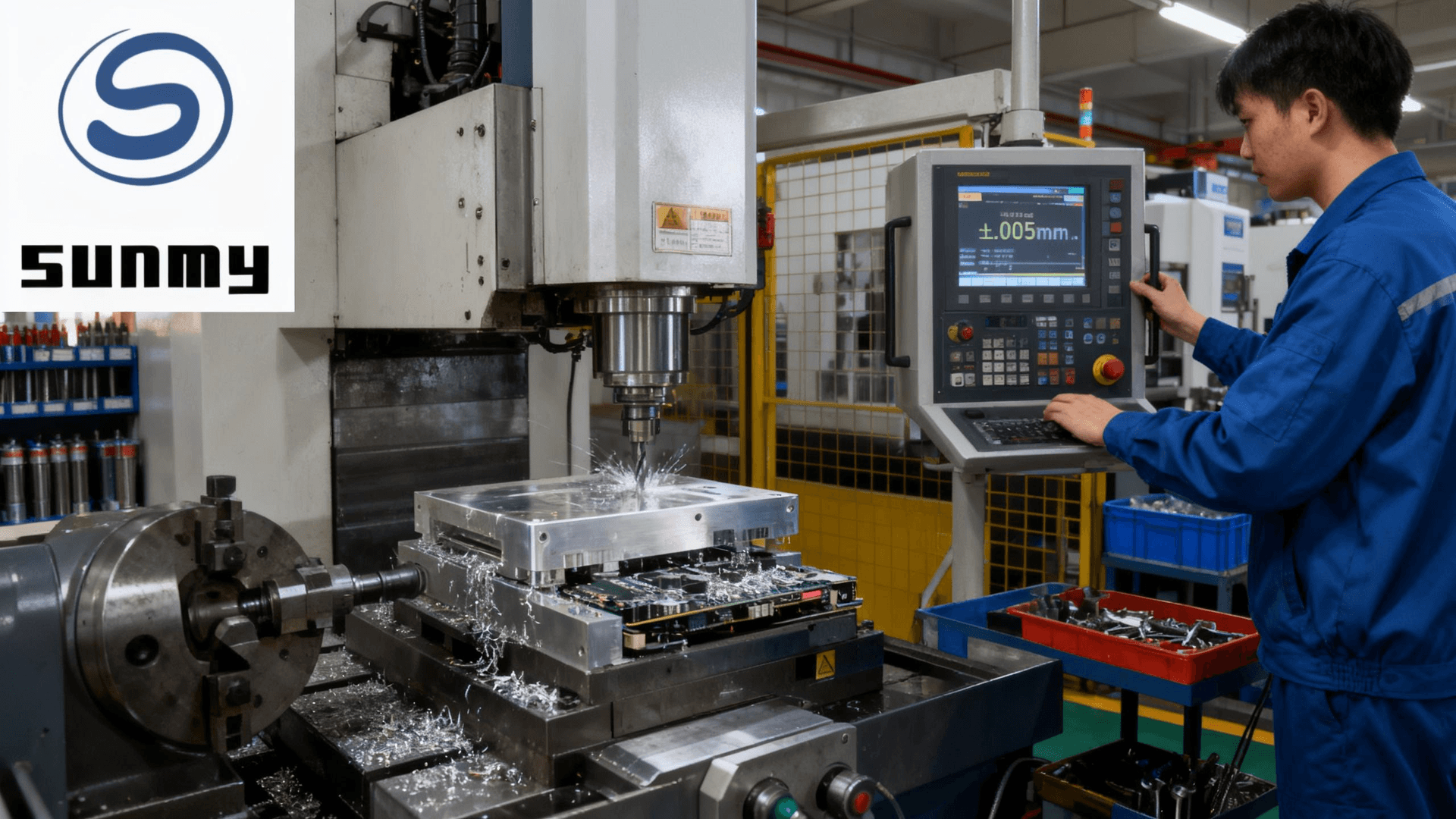

- CNC Machining Service: For high-precision parts like custom aluminum machining parts for electronics or precision machining for medical equipment parts, our 5-axis CNC machines deliver tolerances as tight as ±0.005mm. We regularly produce custom lathe parts manufacturer solutions for clients in aerospace, medical, and automotive industries.

In-House CNC Machining Equipment - Die Casting Manufacturer: As a trusted aluminum die casting parts supplier, we specialize in automotive components customization and industrial parts, using high-pressure die casting to create complex shapes efficiently.

- Stamping & Injection Molding: Our stamping service for stainless steel brackets handles high-volume production with consistent quality, while our injection molding for industrial components caters to precision plastic components needs – from small electronic parts to large industrial housings.

Every production line is staffed by skilled technicians and monitored by real-time quality checks, ensuring that even complex custom spare parts or injection molding solutions meet your exact specifications. Our commitment to in-house manufacturing is why clients across the globe choose us as their custom parts manufacturer in China – no middlemen, no delays, just reliable production.

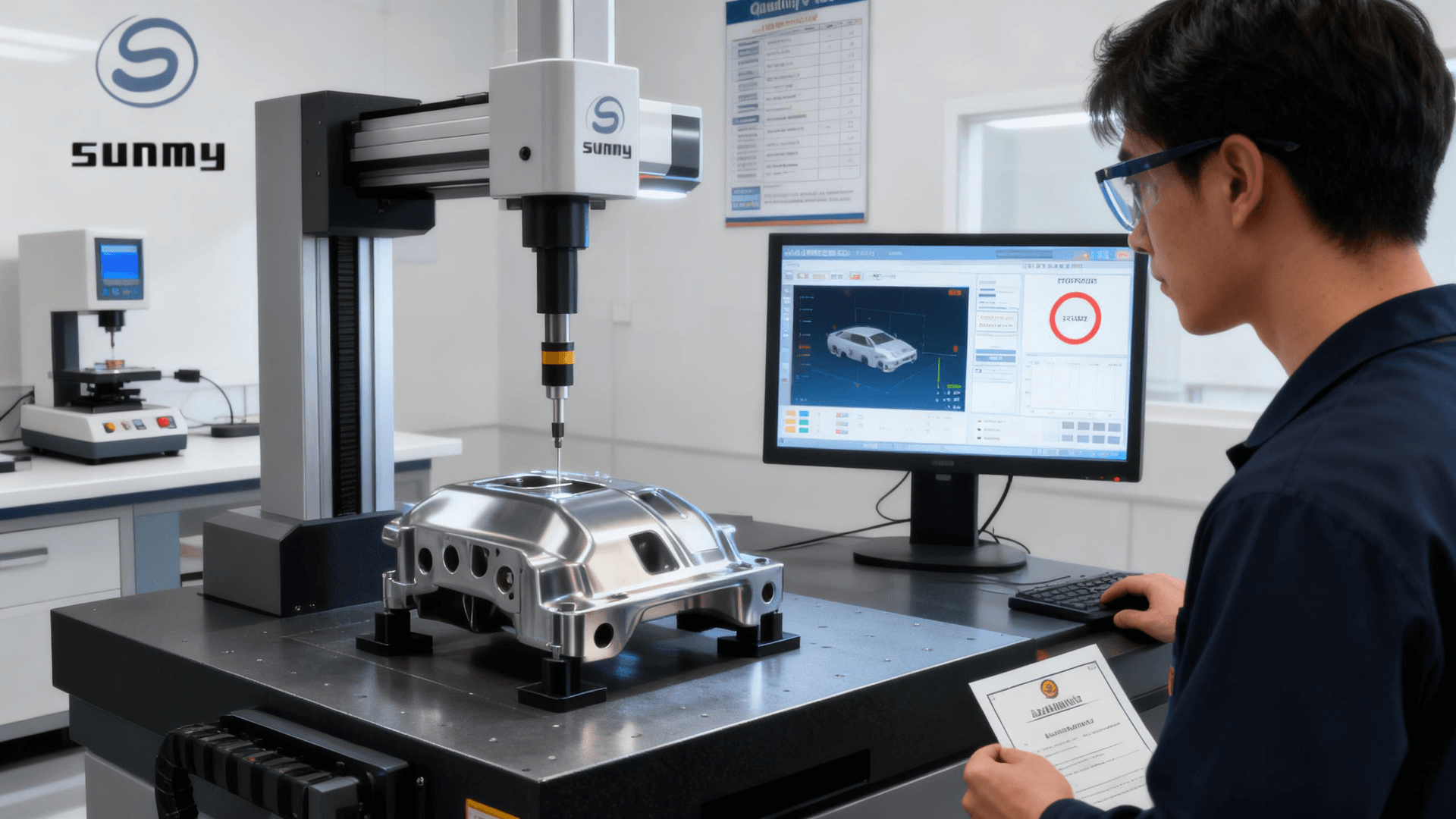

Step 3: Rigorous Quality Control – Because Precision Matters

For custom parts, quality isn’t optional – it’s critical. That’s why Sunmy has a strict quality control (QC) process in place, from raw material inspection to final product testing. Our QC team uses advanced tools like coordinate measuring machines (CMM), hardness testers, and optical comparators to verify:

- Material integrity (e.g., ensuring aluminum for custom aluminum machining parts for electronics meets ASTM standards).

- Dimensional accuracy for custom metal parts and precision plastic components.

- Functional performance (e.g., testing automotive components customization for durability under extreme conditions).

We recently worked with a European medical device company needing precision machining for medical equipment parts – a sector where failure is not an option. Our QC process caught a minor dimensional deviation early, allowing us to correct it before production ramped up. The result? A 100% pass rate and a long-term partnership.

This dedication to quality is why we’re a trusted custom electronic components manufacturer and industrial parts supplier – we don’t just deliver parts; we deliver peace of mind.

Step 4: On-Time Delivery – Global Logistics Made Simple

Once your custom hardware is ready, we handle the logistics to get it to your door – whether you’re in the U.S., Europe, or Asia. We partner with reliable freight forwarders to offer flexible shipping options (air, sea, or express), and our team provides real-time tracking updates so you always know where your order is.

For example, a U.S. client needed USA custom hardware parts for a trade show deadline – we expedited production of their custom lathe parts according to drawing and arranged express shipping, ensuring delivery 3 days ahead of schedule. Our ability to balance speed and reliability is why we’re a top choice for custom parts manufacturer in China for time-sensitive projects.

Customer Success Story: Turning Automotive Components into Reality

One of our most impactful partnerships was with a North American automotive supplier needing automotive components customization for electric vehicles (EVs). They required custom metal parts – specifically aluminum brackets and plastic housings – with strict weight constraints and corrosion resistance.

- Challenge: Tight tolerances (±0.01mm), 8-week lead time, and a need for iterative design adjustments.

- Solution: Our professional engineering team collaborated closely with their design team, providing 3D prototypes within 5 days to test fit. We used aluminum die casting parts supplier capabilities for the brackets and injection molding solutions for plastic parts for the housings, optimizing both for weight and strength.

Customer Success Story – EV Automotive Components - Result: On-time delivery of 10,000 units with zero defects. The client has since expanded their order to include custom spare parts and stamping service for stainless steel brackets, citing our fast communication and flexible solutions as key reasons for the long-term partnership.

This story isn’t unique – it’s how we approach every project. Whether you’re a startup needing small-batch OEM metal parts or a Fortune 500 company requiring high-volume custom lathe parts manufacturer services, we tailor our process to your needs.

Why Choose Sunmy Hardware as Your Custom Parts Manufacturer in China?

With so many China suppliers offering custom hardware manufacturer services, what makes Sunmy different? Here are the core advantages that set us apart:

1.Professional Engineering Team: Our engineers have an average of 10+ years of experience in custom manufacturing, with expertise in industries like automotive, electronics, and medical.

2.Fast Communication: We respond to inquiries within 12 hours, provide regular project updates, and offer 24/7 support for urgent needs – no language barriers, no delays.

3.Integrated Production Capabilities: From casting to injection molding, we handle every step in-house, ensuring quality control and shorter lead times.

4.Flexible Solutions: Whether you need a single prototype or mass production of custom metal parts, we adapt to your volume and budget.

5.Proven Track Record: We’ve served clients in 30+ countries, including the U.S., Germany, and Japan, with a 98% customer retention rate.

Ready to Turn Your Drawing into Delivery?

At Sunmy Hardware, we believe custom manufacturing should be simple, reliable, and tailored to your needs. Whether you’re looking for CNC machining service, aluminum die casting parts supplier, automotive components customization, or any other custom hardware solution, we’re here to bring your design to life.

Explore our Production Capability to learn more about our manufacturing processes, or visit our About Us page to discover our story and team. When you’re ready to get started, send us your drawing or project details via our Contact Us page – our engineering team will reach out with a free quote and design consultation within 12 hours.

As a trusted custom parts manufacturer in China, we’re committed to delivering the precision, communication, and flexibility you need to succeed. Let’s build something great together – from drawing to delivery.