Unlock Agile Custom Manufacturing: How Shenzhen Sunmy Hardware Masters Supply Chain Resilience and Digital Innovation

In today's volatile global market, businesses face unprecedented challenges—from supply chain disruptions to rising demand for personalized solutions. At Shenzhen Sunmy Hardware Co., Ltd., we empower clients with end-to-end custom manufacturing that turns complex designs into reality. Leveraging our robust production ecosystem, including casting, lathe, machining, stamping, and injection molding, we deliver precision parts that drive your success. Discover how our 2016-founded, Shenzhen-based expertise can future-proof your operations.

Introduction: The Evolving Landscape of Custom Manufacturing

The manufacturing sector is undergoing a seismic shift, driven by recent global events and technological advancements. According to 2023 industry reports (e.g., from McKinsey and Deloitte), over 65% of companies now prioritize supply chain resilience and digital transformation to mitigate risks like geopolitical tensions or material shortages. For firms seeking reliable partners, this means choosing manufacturers who offer not just production, but agile, customized solutions. Enter Shenzhen Sunmy Hardware—a premier trade-manufacturing hybrid since 2016. Nestled in Shenzhen, China's tech hub, we specialize in transforming your blueprints, samples, or vague concepts into high-quality, bespoke hardware components. Our team's unparalleled development prowess and integrated facilities (covering casting, lathe, machining, stamping, and injection molding) ensure we meet diverse global demands efficiently. In this blog, we'll explore current industry hotspots and how Sunmy Hardware stands out as your trusted ally. Visit us at sunmyhardware.com to start your custom project today.

Hotspot 1: Navigating Supply Chain Resilience in a Fragmented World

Supply chain disruptions have dominated headlines since the pandemic, with 2023 data showing a 40% increase in companies seeking localized or diversified manufacturing partners (source: World Economic Forum). Events like port congestions or trade wars highlight the need for resilience—where production isn't just fast, but adaptable and risk-proof. At Sunmy Hardware, we address this through our end-to-end capabilities.

- Why It Matters for You: As a client, unpredictable delays can cripple your timelines and budgets. Our Shenzhen base provides strategic access to Asia's supply networks, reducing lead times by up to 30%. For instance, when a U.S. automotive client faced component shortages last year, our in-house casting and machining lines allowed rapid prototyping and scaling—delivering 10,000 custom parts in under four weeks. This agility stems from our complete production ecosystem: from initial design validation to final quality checks, all under one roof. No more juggling multiple suppliers; we handle everything, ensuring consistency and speed.

- Our Approach to Resilience: Beyond geography, our strength lies in flexibility. With advanced lathe and stamping technologies, we accommodate last-minute changes or small-batch orders without compromising quality. Big data analytics reveal that clients value transparency—so we integrate real-time tracking via digital tools, letting you monitor progress from drawing to delivery. This not only builds trust but aligns with the trend toward "nearshoring" or regional hubs. By partnering with us, you gain a buffer against global volatility, turning potential crises into opportunities for innovation.

Hotspot 2: Embracing Digital Transformation for Smarter Customization

Digital transformation is no longer optional—it's a $1.8 trillion industry movement (per Gartner 2023), revolutionizing how manufacturers handle customization. Technologies like AI-driven design and IoT-enabled machining enable hyper-personalized production, meeting the surge in demand for unique, on-demand parts. Sunmy Hardware excels here, blending cutting-edge tech with hands-on expertise.

- The Power of Personalization: Today, 70% of B2B buyers expect tailored solutions (Accenture data), whether for aerospace components or consumer electronics. Our team thrives on this: share your sketches, CAD files, or physical samples, and we deploy rapid development cycles. For example, a European client needed intricate injection-molded parts with tight tolerances; using 3D scanning and simulation software, we optimized the design digitally before moving to production, slashing errors by 25%. This digital-first mindset extends to our machining and stamping processes, where automation ensures precision across metals, plastics, and alloys—perfect for complex geometries or low-volume runs.

- Integrating Sustainability and Efficiency: Digital tools also support sustainability, a key sub-trend in 2024. By minimizing waste through virtual prototyping and energy-efficient injection molding, we help you reduce carbon footprints—a win for eco-conscious brands. Our facility in Shenzhen adheres to green standards, recycling materials and optimizing resource use. This holistic approach not only future-proofs your projects but enhances cost-effectiveness, with digital workflows cutting costs by 15-20% on average.

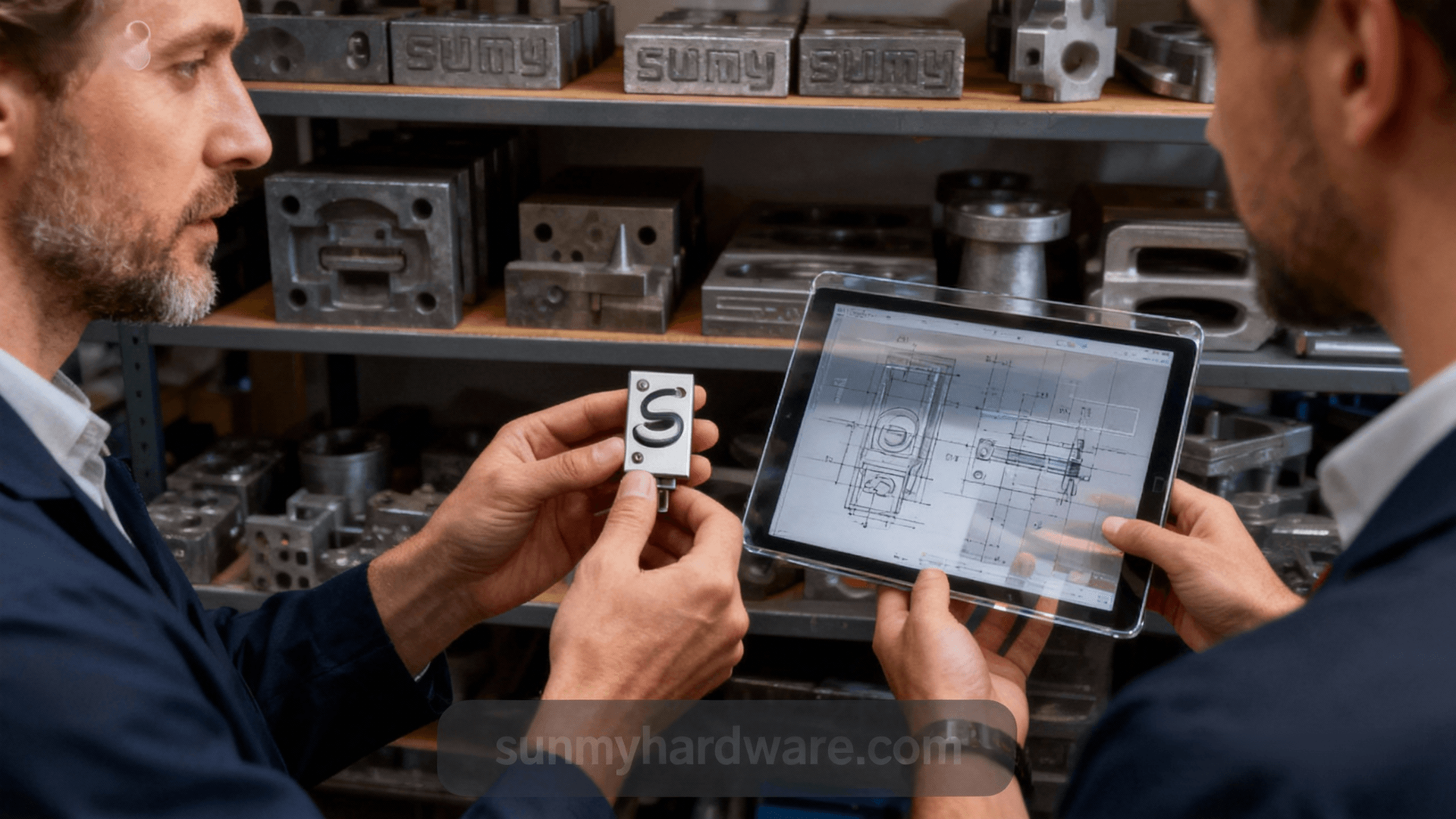

Why Choose Shenzhen Sunmy Hardware? Core Strengths and Client Success

Founded in 2016, Sunmy Hardware has evolved into a powerhouse for custom manufacturing, serving industries from automotive to consumer goods. Our Shenzhen location is strategic, but it's our team and tech that set us apart.

- Unmatched Development and Production Capabilities: Unlike generic suppliers, we offer a full suite of services:

- Casting & Lathe: For durable metal parts, our foundry and CNC lathe operations handle everything from prototypes to mass production.

Machining & Stamping: Precision milling and forming for intricate designs, ideal for high-strength applications. - Injection Molding: Versatile plastic solutions, from small connectors to large housings, with quick turnaround.

This integrated system means no outsourcing delays—your project flows seamlessly from concept to crate. Our engineers, with decades of collective experience, excel at interpreting vague requirements; send us a rough idea, and we refine it into manufacturable brilliance. - Proven Impact: Clients worldwide, like a German industrial equipment maker, praise our ability to innovate under pressure. When they needed a custom-stamped component with zero defects, our iterative prototyping and rigorous QA delivered ahead of schedule, boosting their market launch. Such stories underscore our commitment: we're not just a vendor, but a partner invested in your growth.

Conclusion: Partner with Us for Future-Ready Manufacturing

In an era defined by change, Sunmy Hardware is your anchor. By mastering industry hotspots like supply chain resilience and digital innovation, we transform challenges into competitive advantages. Whether you're a startup or a multinational, our Shenzhen-based team is ready to bring your vision to life with speed, precision, and creativity. Don't settle for off-the-shelf solutions—embrace customization that drives results.

Call to Action: Ready to elevate your hardware projects? Visit sunmyhardware.com to explore our services, request a quote, or discuss your custom needs. Follow us on social media for industry insights and success stories. Let's build the future, together.